These portalkranar are mainly used for girder lifting, bridge transportation and bridge erection tasks in prefabrication plants and are equipped with special spreaders.

Compared with ordinary gantry cranes, these gantry cranes have the advantages of easy and quick installation and dismantling, economical and practical.

- Capacity: 20t-900t

- Span length: 24-55 meters

- Lifting height: 9m-60m

- Working duty: A3

- Working voltage: 220V~690V, 50-60Hz, 3ph AC

- Working environment temperature: -25℃~+40℃, relative humidity ≤85

- Crane control mode: cabin control

Prefabricated (engineering) gantry cranes are designed and manufactured in accordance with national and industry standards, in line with GB/T3811 Crane Design Code and GB/T14406 General Gantry Cranes and other standards. They are suitable for highways, bridge girder yards and bridge erection and other places. Their spreaders can be hooks, spreaders and pin-type moving pulleys. The frame of the gantry crane adopts A-type structure with rigid leg and flexible leg support structure, which increases the overall flexibility and improves the carrying capacity of the gantry.

The truss structure is mainly used in places with large outdoor wind loads due to its relatively small wind area.

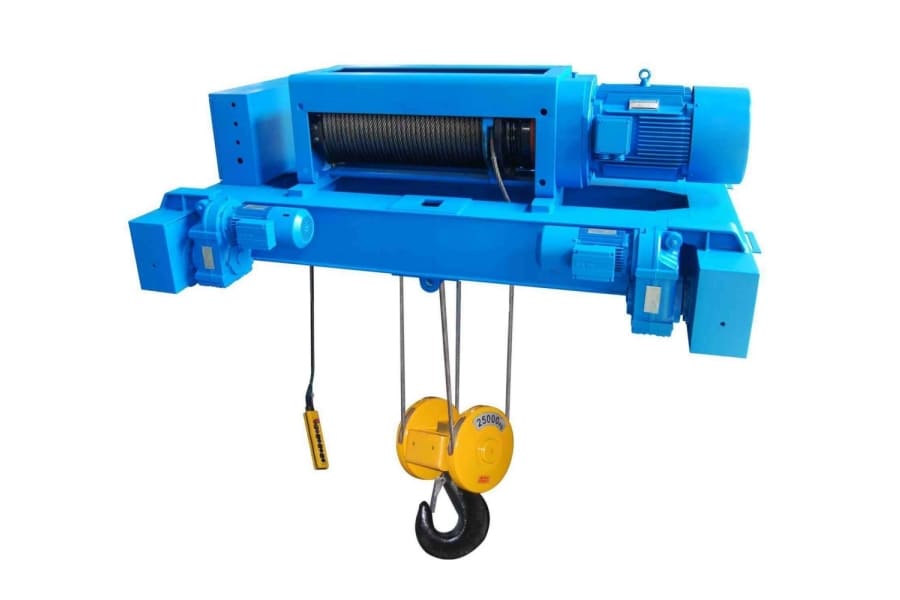

Gantry cranes are composed of steel structure, trolley, crane traveling mechanism and electrical system.

These gantry cranes have the following advantages:

- good rigidity, able to carry heavy loads and remain stable.

- Safety and reliability to ensure safe conduct of lifting operations.

- Advanced performance, providing efficient lifting and transportation capacity.

- Easy to install, saving time and labor cost.

- Easy to transport, adapting to the needs of different sites.

- Economical and practical, with high cost-effective.

Pouring yard gantry cranes are widely used in pouring yards in railroad and bridge construction. They play an important role in the manufacture and transportation of concrete girders. Considering that casting yards are usually located in open fields and have a large area, the dimensions and power requirements of the gantry cranes should be taken into account. Depending on the requirements of the specific case, we can provide a detailed solution to meet the customer’s needs.

A customer from the Middle East needed a double girder gantry crane to move concrete beams in a pouring yard. These beams have a maximum deadweight of 120 tons and a length of 24 meters. To ensure safety, our technicians suggested using two 70-ton gantry cranes for synchronized operation. In this way, the two cranes can work together to move the concrete beams, or they can be operated separately and independently when required.

We also added oil-fired generators to the cranes in order to accommodate the fact that foundries are often located in the countryside and there is no electrical utility available.

In addition, one of our customers requested two sets of 30+30 ton gantry cranes for his foundry. They wanted the two cranes to be synchronized and needed four trolleys to be able to operate synchronously.

When discussing the details of the crane solution, our engineers provided an accurate design of the track foundations so that the customer could easily carry out the construction of the track foundations. As for the power supply, our engineers suggested the use of cable reels to save costs.

Apart from that, we also provide technical support during crane assembly and commissioning. Our technicians will be on site from the very beginning and provide support until the commissioning work is successfully completed.