1. Transmission form of vrhnji mostni žerjav trolley operating mechanism

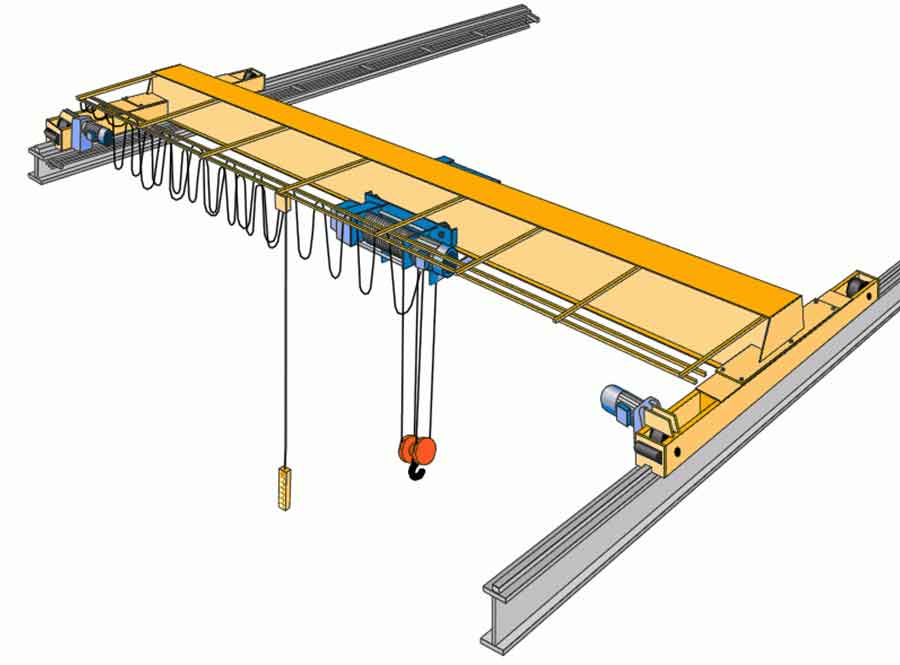

The trolley operating mechanisms of small and medium-sized cranes all adopt the form of centralized drive, as shown in Figure 2-11(a), while the trolley operating mechanisms of large cranes usually adopt the form of separate drives.

2. Composition of the crane trolley operating mechanism

The trolley operating mechanism consists of a motor, a coupling, a vertical reducer, and a wheel set. The brake wheel and its corresponding brake are installed on the motor shaft.

3. Technical requirements for crane trolley operating mechanism

① The operating mechanism of the sevencrane top running overhead crane for sale trolley must be equipped with brakes so that it can stop safely within the allowable braking stroke range after power failure.

②The brake should be inspected and adjusted every 2-3 days.

③Terminal stroke limiters must be installed at both ends of the crane trolley’s stroke, and a limit safety contact ruler must be installed at the bottom of the trolley frame to ensure that when the trolley reaches the end, it hits the limiter arm and opens the contacts to cut off the power and stop. .

④ A buffer must be installed at the bottom of the crane trolley frame, and baffles must be welded to the corresponding parts of the webs at both ends of the main beam so that they collide with the collision head of the buffer to prevent the car body from continuing to run and play a buffering role.

⑤A stopper should be welded to the cover above the end of the main beam to ensure that the car does not derail.

⑥When the trolley is running, each wheel tread should be in contact with the track at the same time. The gap between the driving wheel tread and the top surface of the track should not be greater than 0.1mm; the gap between the driven wheel tread and the top surface of the track should not be greater than 0.5mm. When the “three legs” phenomenon occurs on the car, it must be repaired and cannot be worked while sick.

⑦ When the industrial top running overhead crane manufacturers trolley wheel has a single rim, the rim should be installed close to the outside of the track and must not be installed backwards.

⑧Similar to the cart, a track sweeper plate should be installed in front of the wheels of the trolley. The gap between the lower edge of the track sweeper plate and the top surface of the rail is 10mm.