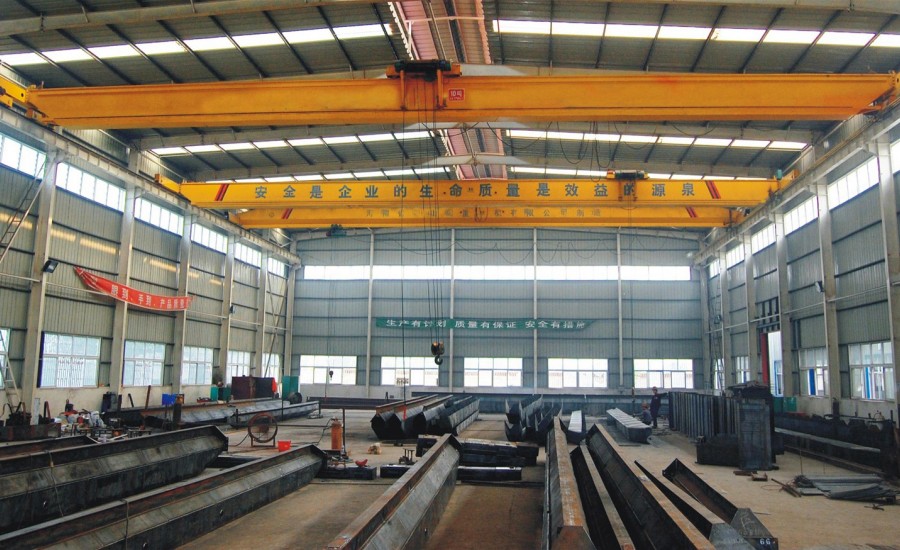

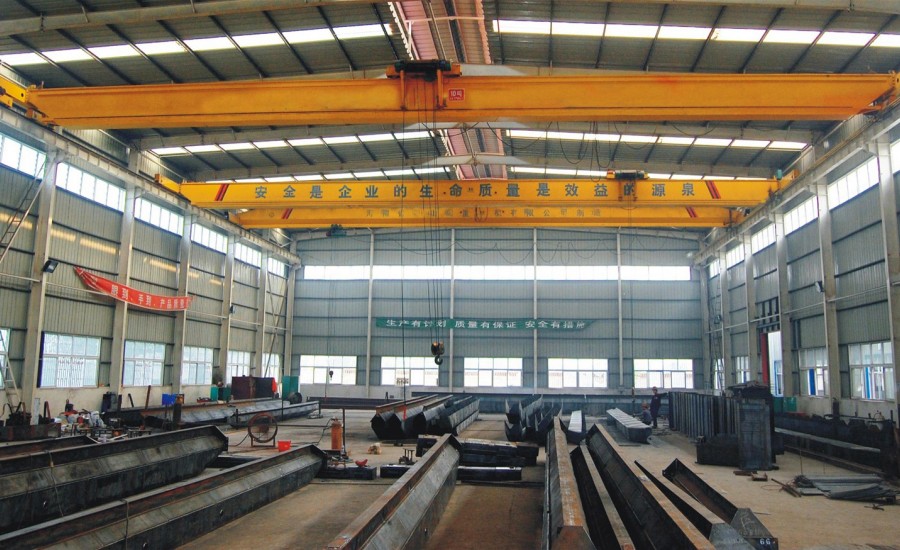

Single (double) girder overhead traveling crane for sale is widely used engineering lifting equipment with high work efficiency, and their advantages are particularly evident in the following aspects.

1. Light weight. The hoisting mechanism, main beam structure, and accessories are all made of high-strength materials, which improves the bearing capacity, reduces its own weight, and reduces wheel pressure.

2. Small footprint. The limit distance from the hook to both sides is small, the working range is large, and the height from the rail surface is small, which effectively utilizes the workshop space.

3. Low operation and maintenance costs. Due to the small wheel pressure and small overall size, the investment in the preliminary engineering such as workshops can be reduced, and the product performance is reliable and durable, which reduces the additional cost required for the later product in the use process to a lower level. The selection of high-quality and high-performance components greatly reduces the workload of maintenance and repair, reduces the total installed power, and saves the cost of use.

4. High working performance. Using frequency conversion technology, under the double support of overhead bridge crane manufacturers, the equipment can run smoothly, reduce the impact on the workshop, and realize accurate positioning of lifting objects. monorail overhead crane suppliers help your cranes to be automated, intelligent and unmanned.

Precautions for single (double) girder cranes?

1. Be sure to check all kinds of spreaders before operation. Make sure that the spreader is complete and in good condition. It is impossible to work as overhead bridge crane manufacturers if the assemblers are defective.

2. Also check the condition of the rope. Make sure the rope is secure and not loose or broken. If there is an object with an edge, a protector needs to be added between the object and the rope to prevent the rope from breaking.

3. Find the center of gravity of the weight. Find out the center of gravity of the heavy object to avoid the cable pull phenomenon of electric overhead traveling crane cost. Special lifting items need to be operated by staff.

4. When lifting objects, don’t act too hastily. Be sure to wait a while until the goods stabilize before proceeding. No sundries are allowed on the heavy objects, and no one is allowed to stand on them. When lifting, irrelevant personnel are not allowed to pass under the object.

5. Work safety measures should be improved. For example, workers must wear hard hats, professionals must have unified command, and various departments must coordinate their work. When the object is off the ground, check whether the steel wire rope and other parts are safe. If unsafe, stop monorail overhead crane suppliers to check.

Understanding the precautions for starting electric overhead traveling crane cost can help us avoid construction risks in time and prevent problems before they happen. Sevencrane focuses on research and development: an integrated provider of automated, unmanned, and intelligent crane control systems. It is an overall solution for your crane automation, digitization and intelligence.