Introduction

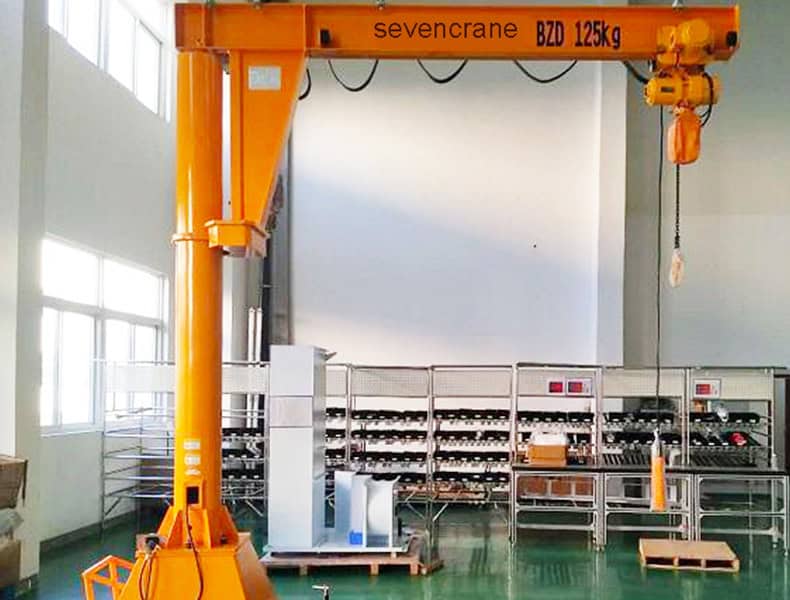

☑Portable mobile jib cranes typically consist of a vertical mast or column, a horizontal boom or arm, and a base with wheels or casters for mobility. The mast is usually adjustable in height to accommodate different lifting requirements, and the boom can rotate to provide a wide range of coverage. The base is equipped with wheels or casters that allow the crane to be moved easily from one location to another. It is a type of crane that is designed to be easily transported and used in various locations. Unlike fixed jib cranes, which are permanently installed in a specific area, portable mobile jib cranes offer flexibility and mobility, allowing them to be used in different work environments.

☑Portable mobile jib cranes come in various load capacities, ranging from light-duty models capable of lifting a few hundred pounds to heavy-duty models that can handle several tons. The lifting capacity and reach of the crane depend on its specific design and construction. These cranes are designed to be lightweight and compact, making them suitable for applications where frequent relocation is necessary or where space is limited. They are commonly used in construction sites, workshops, warehouses, and other industrial settings where lifting and material handling tasks are required in multiple areas.

Advantages

-Enhanced Flexibility: Easily movable to different workstations, reducing the need for multiple fixed cranes.

-Increased Productivity: Quick setup and operation lead to faster and more efficient material handling.

-Space-Saving Design: Compact structure allows for use in confined spaces without compromising lifting capacity.

-Cost-Effective Solution: Reduces the need for permanent crane installations while maintaining high efficiency.

-Improved Safety: Designed with safety features to ensure secure lifting and minimize workplace accidents.

Application

-Workshops & Warehouses: Efficiently handle materials and components in assembly and storage areas.

-Manufacturing Facilities: Ideal for lifting and positioning heavy parts in production lines.

-Construction Sites: Provides temporary lifting solutions where permanent cranes are not feasible.

-Loading Docks & Ports: Assists in loading and unloading materials from trucks and ships.

-Automotive & Aerospace Industries: Supports handling of engines, body frames, and other heavy parts.

Safe Operation of Portable Mobile Jib Crane

- When the crane is operating, parking, or traveling, it should maintain a safe distance from the ditch.

- During operation, the crane should be placed on a flat and solid ground, and the inclination of the fuselage should not exceed the specified value of the machine.

- When traveling, the boom should be placed on the bracket, and the hook should be hung on the hanging rope and tightened.

- The outriggers should be supported before lifting; after lifting, the boom should be placed on the bracket to retract the outriggers.

- The clutch lever should be locked during operation.

- The distance between the fuselage and the load must be greater than the minimum safe distance from the discharge wire.

- The boom should move slowly and emergency braking is not allowed. The deflection of the boom should be checked when approaching full load.

- When the load is traveling, the load should be located directly in front of the crane, not too high from the ground, and the weight should not exceed 2/3 of the permitted lifting weight. Pull the return rope and drive slowly.

Of course, we also offer a customized service.To provide you with the most accurate and tailored design solution, please share the following details:

1.Lifting Capacity:

Please specify the maximum weight your crane needs to lift. This critical information enables us to design a system that can handle your loads safely and efficiently.

2.Lifting Height (Hook Center to Ground):

Indicate how high the hook needs to reach from the ground level. This helps determine the appropriate mast or girder height for your lifting operations.

3.Power Supply:

Specify the voltage of your power source.Different voltage requirements affect the electrical components and wiring design of the crane.

4.Working Conditions:

Describe the types of materials you’ll be lifting and the ambient temperature. These factors influence the choice of materials, coatings, and mechanical properties for the crane to ensure its durability and optimal performance.

5.Workshop Drawing/Photo:

If possible, sharing a drawing or photo of your workshop would be highly beneficial. This visual information helps our team better understand your space, layout, and any potential obstacles, allowing us to tailor the crane design more precisely to your site.

Maintenance and Warranty

-Maintenance Schedules and Best Practices: Regular maintenance ensures the crane remains in good working condition:

◉Maintenance Schedules: Follow a recommended maintenance schedule that includes regular inspections, lubrication, and part replacements. Adhering to these schedules helps prevent breakdowns and extends the crane’s service life.

◉Best Practices: Implement best practices for maintaining the crane, such as keeping it clean, checking for wear and tear, and ensuring all safety features are functioning correctly.

-Warranty Coverage and After-Sales Support: Ensure comprehensive support and coverage for your crane investment:

◉Warranty Coverage: Verify the warranty terms provided by the manufacturer or supplier, including the duration and what is covered. A good warranty provides protection against defects and potential issues.

◉After-Sales Support: Access to reliable after-sales support is important for addressing any issues that arise after purchase. This support may include technical assistance, repair services, and spare parts availability.

By carefully considering these factors and ensuring proper installation, training, maintenance, and support, you can maximize the benefits of your portable jib crane and ensure it performs effectively and safely in your operations.