Overview

♦SEVENCRANE can produce endcarriages for three different types of cranes, including double girder box structures, double girder profile structures and single girder structures. The application standards of the European-style endcarriages produced by our company are suitable for the large truck operation structure of various types of bridge cranes, and the car structure of the large and medium-sized lifting equipment lifting structure.

♦Equipped with a driver module that is constructed as an integrated structure with a reducer, motor and brake system. According to requirements, it can also form a suspension drive car. Specially designed end beams and geared sockets for drive modules.

♦Finally, the four longitudinal welds of the end beam are welded by electric welding, and the longitudinal seam between the lower flange plate and the web plate must be welded first. Fully consider that the welding of the end beam and the load-bearing beam is on the inner side of the beam, so when assembling and welding the end beam, pay attention to the orientation and sequence of each welding, so that the end beam has a certain amount of outward bending before the load-bearing beam is welded. After the end beam is made, the main technical requirements are also tested, and the position of the electric end beam that does not meet the specifications should be corrected.

SEVENCRANE manufactures a wide range of industrial lifting equipment, including overhead cranes, gantry cranes, jib cranes, as well as crane end carriages, end beams, wheels, cable reels, electric hoists, winches, and more.

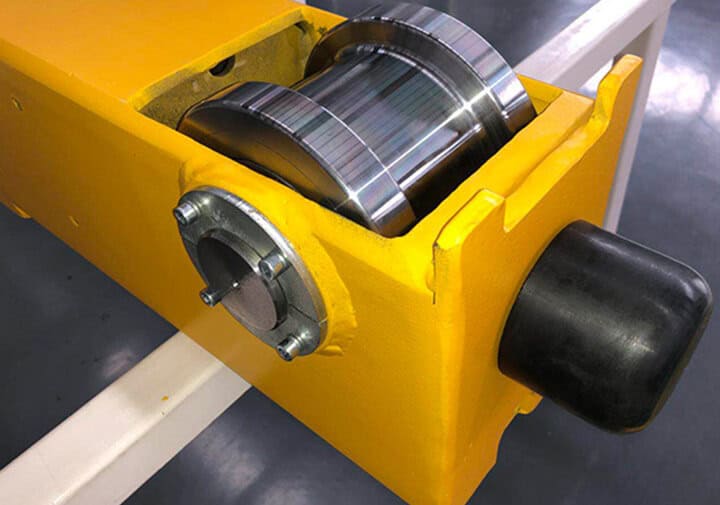

1.Single Girder End Truck

Single Girder End Carriage is suitable for Crane with Capacity less than 32 tons. Its structure is simple, and its maintenance is convenient. It has two high torque driving motors, which is suitable for most of the use environment.

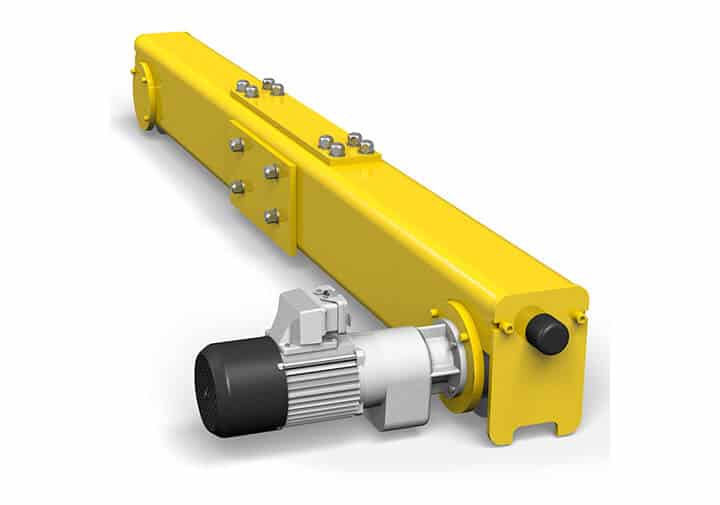

2.Double Girder End Truck

Double Girder End Carriage is suitable for double girder cranes. The rated load is greater, and it is used in high load environment. It has a traveling wheel installed, running smoothly, and having less noise.

3.Underhung Crane End Truck

Underhung Crane End Carriage is used in Suspended cranes, compared to ordinary End Carriage, and its wheels are specially designed for suspension, and its weight is lighter.

4.Double Track Power Trolley

Double Track Power Trolley has a larger capacity and more than 50T. Two high torque crane motor are used in double beam driving.

Those four types of end carriage suitable for a variety of working conditions, including factories, workshops, outdoor, warehouses, etc.Should you need crane spare parts,SEVENCRANE is here for you,welcome to send a free inquiry.

Key Features

– Robust Construction: Our endcarriages are constructed from high-quality materials to ensure strength and durability. It is designed to withstand the rigors of daily use in industrial settings.

– Smooth Operation: The wheels on our endcarriages are engineered for smooth and precise movement, allowing for efficient and controlled load handling.

– Easy Installation: Our endcarriages are designed for easy installation, minimizing downtime and allowing for quick integration into your existing crane system.

– Customizable Options: We offer a range of customizable options to meet the specific requirements of your application, including different wheel configurations and sizes.

Benifits

-Increased Productivity: The workshop crane endcarriages with wheels enables efficient movement of loads, helping to streamline your operations and improve productivity.

– Enhanced Safety: Our endcarriages are designed with safety in mind, providing stable support for the crane and reducing the risk of accidents in the workplace.

– Long-Term Reliability: With its durable construction and high-quality components, our endcarriages are built to provide reliable performance over the long term, minimizing maintenance requirements and downtime.

Why Choose Us

- High-Quality Materials: We use high-quality materials in the manufacturing of crane end beams, ensuring durability and reliability in heavy-duty applications.

- Precision Engineering: The crane end beams are engineered with precision to meet industry standards and ensure smooth and efficient operation.

- Customization Options: We offers customization options for crane end beams to suit specific requirements, such as different load capacities, spans, and lifting heights.

- Safety Features: The crane end beams are equipped with safety features to ensure safe lifting operations and protect both personnel and equipment.

- Longevity: Endcarriages are designed for longevity, providing a long service life with minimal maintenance requirements.

- Technical Support: We provide technical support and assistance to customers for installation, maintenance, and troubleshooting of their crane end beams.