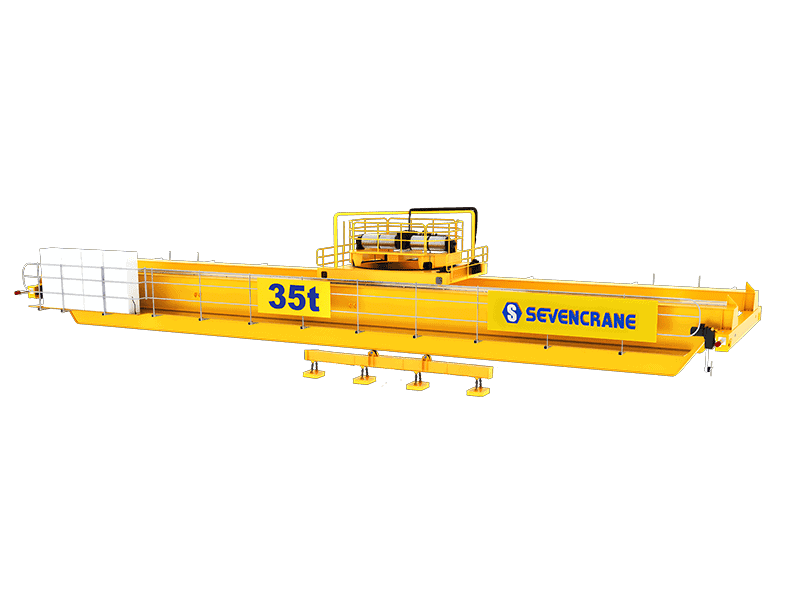

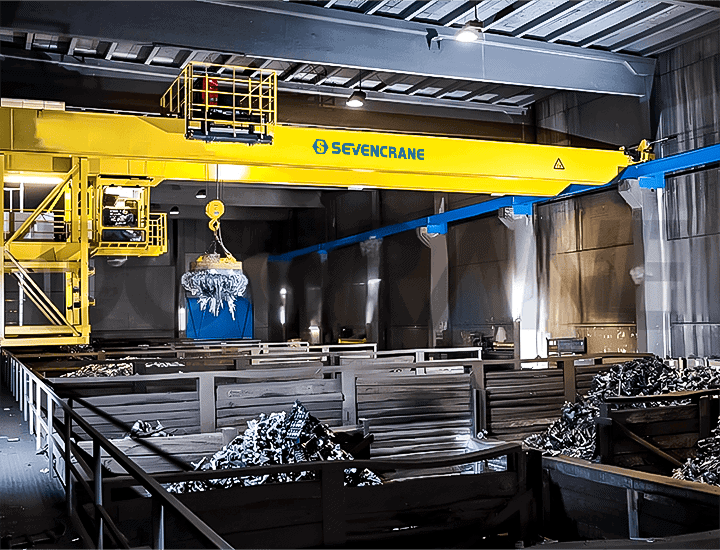

Electromagnetic Overhead Crane is an electric lifting equipment, mainly used for lifting metal loads. It is widely used in metallurgical plants or outdoor working environments, and is particularly suitable for loading and unloading and transporting electromagnetic ferrous metal materials such as ingots, steel and pig iron. The crane is equipped with a detachable electromagnetic plate. The lifting capacity includes the weight of the electromagnetic plate. It has main components such as a box-shaped bridge, a trolley running mechanism, a trolley, electrical equipment and an electromagnetic plate. The operation is carried out through the cab, and a rainproof device is required when used outdoors. The electromagnet is its core component, which absorbs metal objects by powering on and safely transports them to the designated location.

Advantages:

1. Powerful lifting capacity: Compared with other cranes, Electromagnetic Overhead Crane can provide higher lifting capacity and adapt to various heavy-duty operations.

2. Diversified structures: The structural forms are diverse, which can meet the needs of different customers, adapt to complex working environments and specific operating requirements.

3. Low damage rate: The electromagnetic suction cup can be easily adsorbed on smooth surfaces, reducing the risk of hook damage, thereby reducing maintenance costs.

4. Safe and reliable: Electromagnets are used as lifting tools, and the strong magnetic force ensures the stability of objects and prevents personal and property losses caused by falling. In addition, it is equipped with an automatic protection system that can cut off the power supply under abnormal circumstances to ensure the safety of operators.

5. Flexible and efficient: The design is lightweight, with the characteristics of small dead weight and flexible use. It can quickly adjust the position and direction, is suitable for operation in narrow spaces, and significantly improves work efficiency. At the same time, quick start and stop reduce waiting time and improve production efficiency.

6. Easy to operate: The wireless control system is adopted, which is convenient and fast to operate. All lifting, lowering and moving operations can be completed by remote control without manual climbing.

7. Energy saving and environmental protection: Using electromagnets to lift objects is more energy-saving than other cranes, reduces the emission of smoke and harmful gases, and meets environmental protection requirements.

Classification:

1.Parallel hanging beam: The hanging beam is parallel to the main beam, suitable for specific lifting operations.

2.Vertical hanging beam: The hanging beam is perpendicular to the main beam, providing different operating angles and flexibility.

3.Upper rotating beam crane: Designed with upper rotation function, it can achieve more flexible operation during lifting.

4.Lower rotating beam crane: With the characteristics of lower rotation, it is suitable for places where low-height operation is required.

Application areas:

1. Industry applicability: Electromagnetic Overhead Crane is used in conjunction with various lifting machinery and is widely used in industries such as steel mills, foundries, scrap steel processing plants, machining workshops, steel storage and ports.

2. Material handling: Mainly used for lifting and transporting metal materials such as cast iron ingots, steel balls, pig iron blocks and processing chips.

3. Electromagnetic crane function: Suitable for indoor and outdoor loading and unloading and transportation, specializing in handling steel ingots, steel sections, iron, scrap iron and other ferrous metal products.

4. Magnetic beam design: With electromagnetic suction cups as the main lifting tool, the direction of the lifting beam can be parallel or perpendicular to the main beam, suitable for handling long goods, including steel plates, profiles, bars, pipes, wires and coils, etc.

SEVENCRANE has been focusing on crane exports for thirteen years and is committed to tailoring the most suitable crane and transportation solutions for customers. We provide comprehensive installation and maintenance services and support third-party testing of products to ensure that your user experience is worry-free.