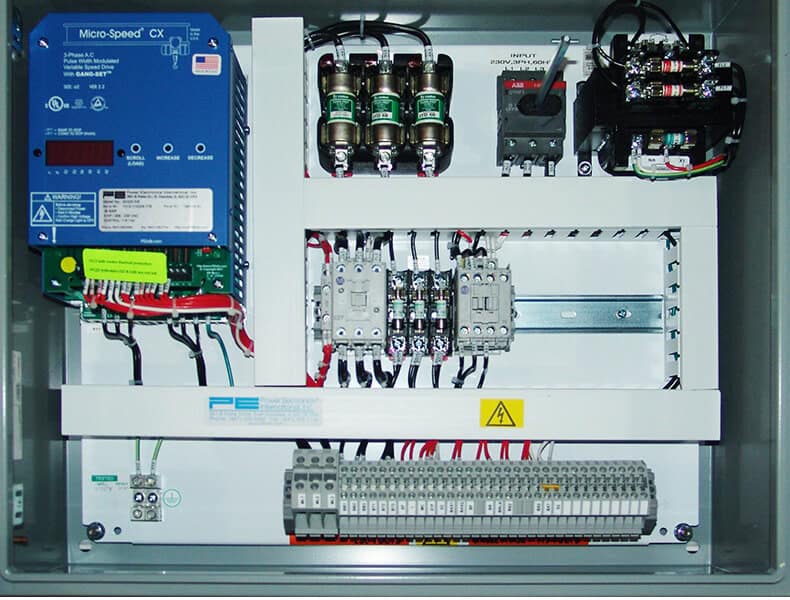

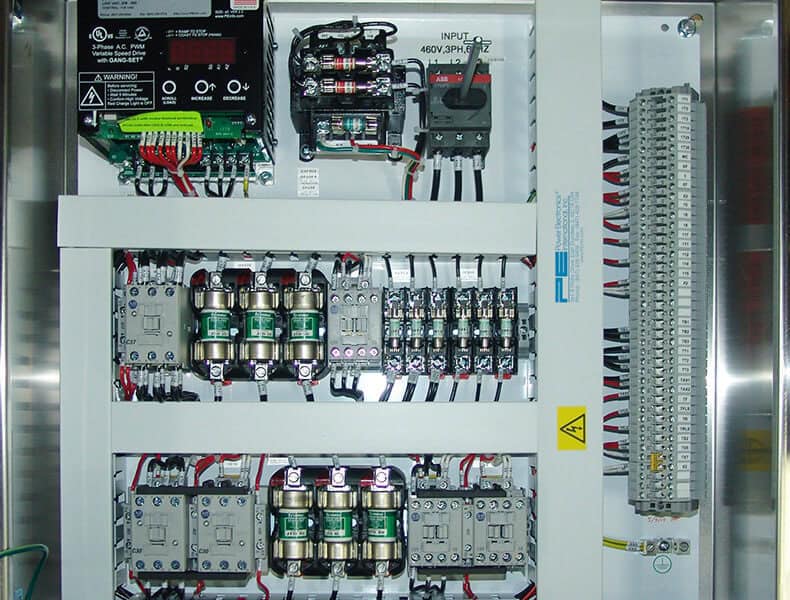

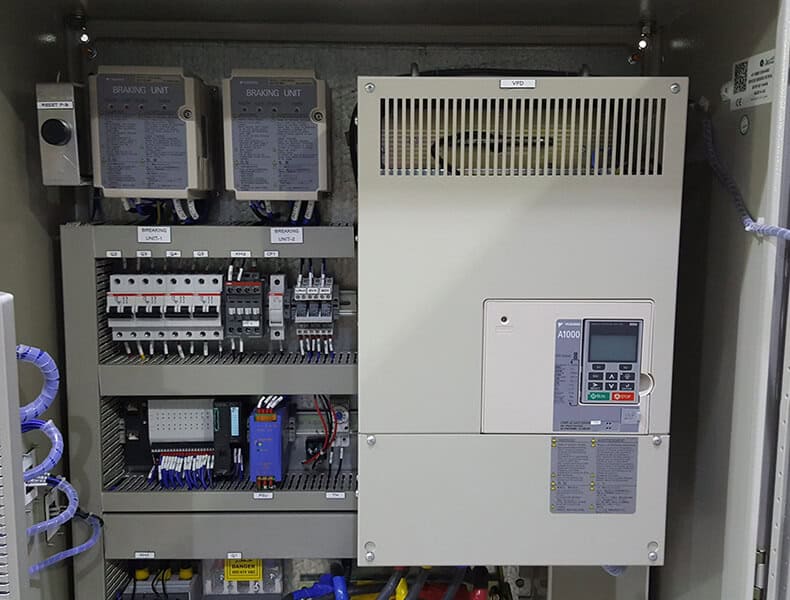

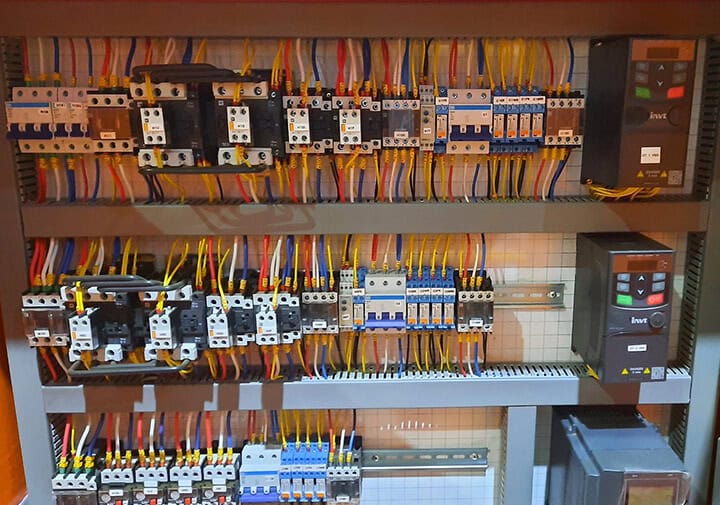

Crane electric panels produced by SEVENCRANE are designed to meet the various needs of users as well as crane specifications and are designed to provide tight control over torque and speed regulation while providing the easiest and most user-friendly operator interface in the industry. Designed to handle the industry’s toughest conditions and environments. If your overhead cranes and hoists operate in extreme temperatures, corrosive chemical environments, or require spark resistance, we can build the drives or panels for you. Every drive is tested and inspected to ensure our drives and panels deliver only the highest level of performance.

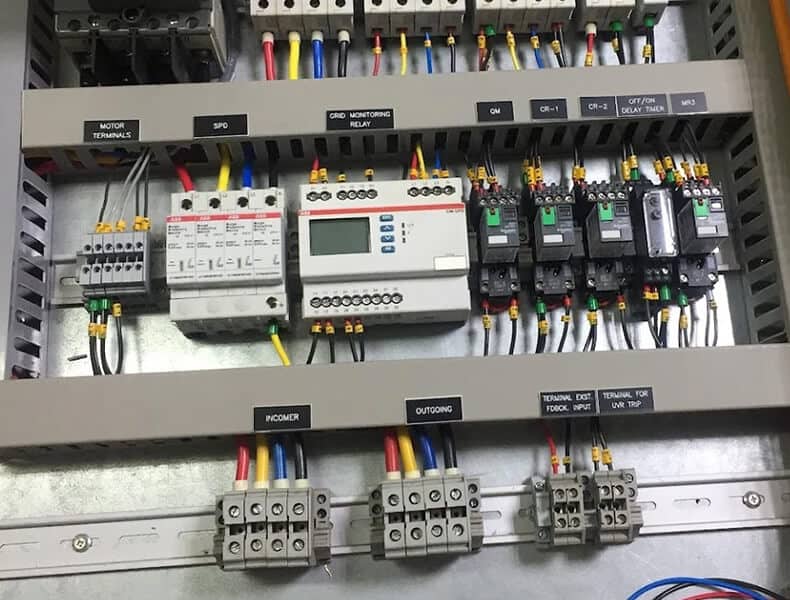

Our electrical panels contain a content composition of Siemens and Omron switch material. The electrical scheme and wiring diagram of each crane produced will be delivered to the customer in the form of documents. Unlike alternative products, all connections use sockets and plugs, making installation, commissioning and maintenance very simple.

By tracking the current market development, we are manufacturing and exporting a series of high-quality crane electrical panels, which are manufactured using quality inspected components and advanced technology that meets international standards. These crane panels are widely used to control the speed of cranes. Our crane electrical panels come in various specifications, which can be customized according to customer specifications and can be provided at the most reasonable price.