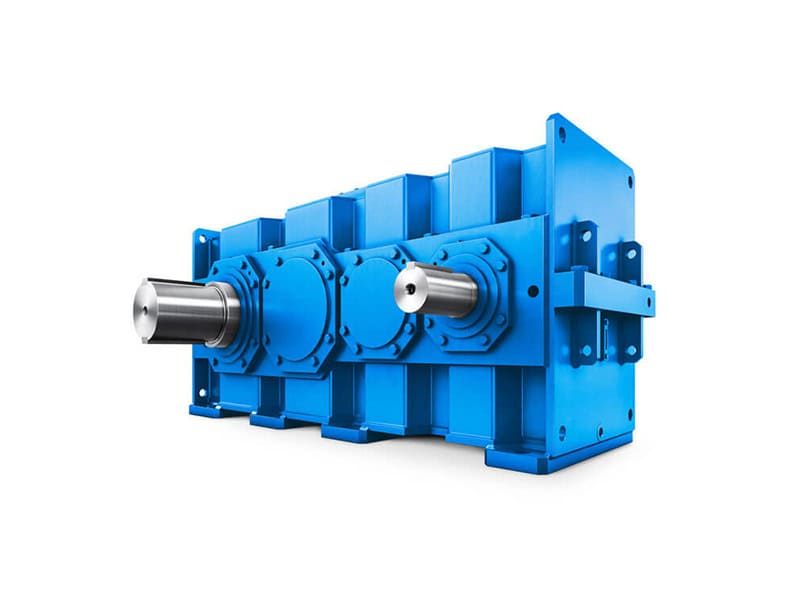

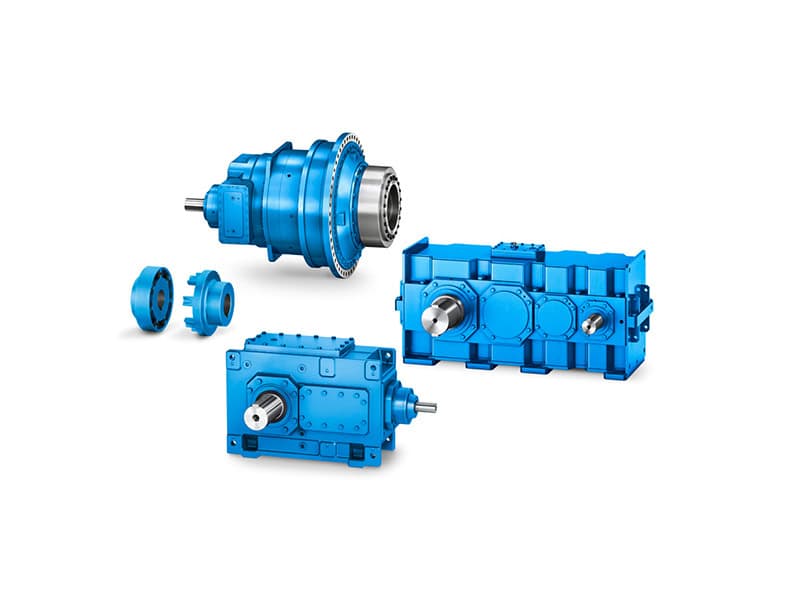

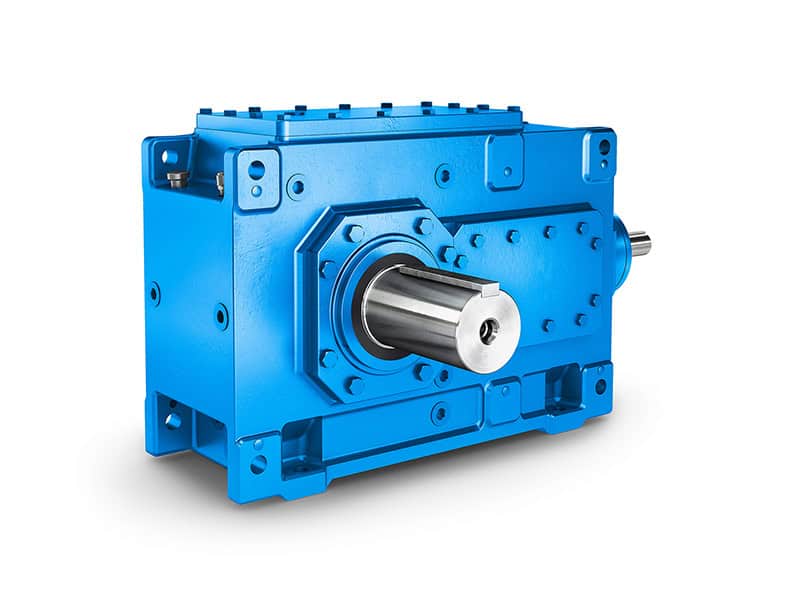

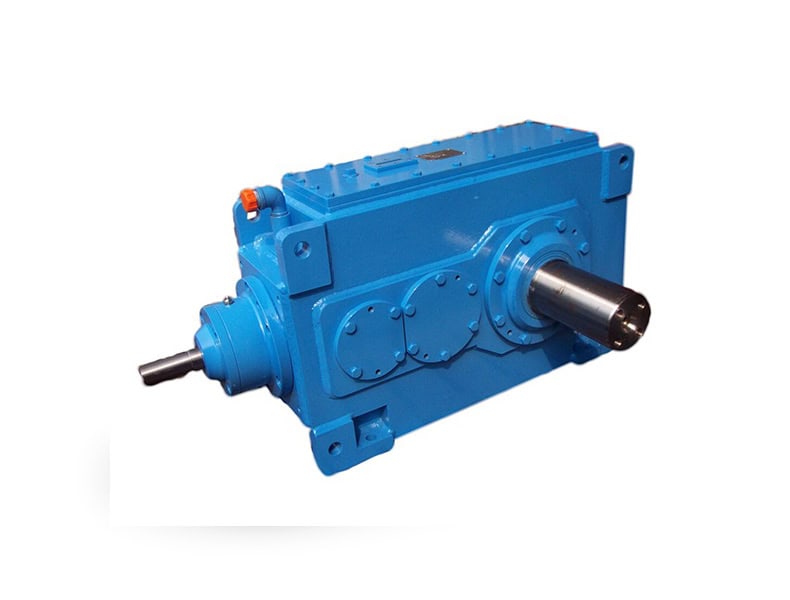

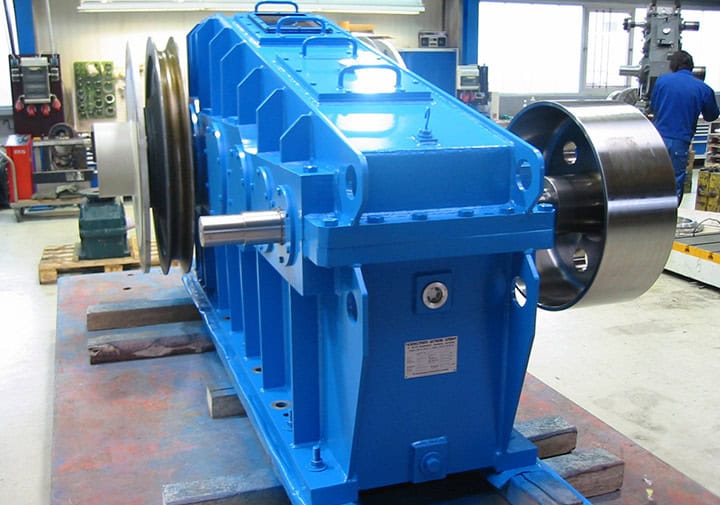

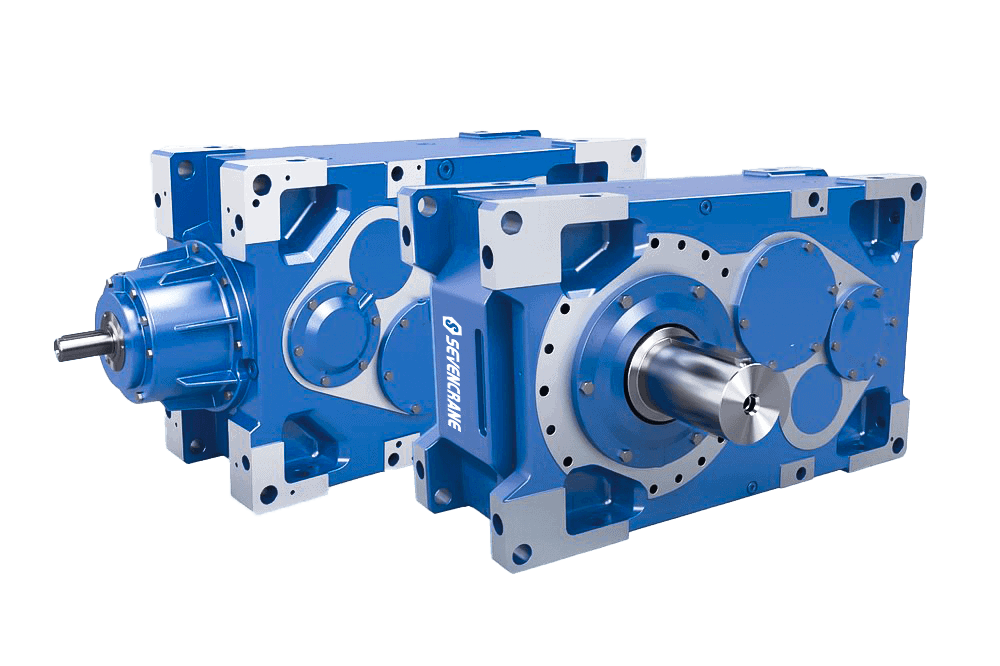

A crane gearbox is a gear system specifically designed and built for a wide range of crane work applications. The bearings used in these gearboxes are frictionless and have a good service life. Equipped with a large oil tank, it can provide maximum thermal efficiency. The gearbox produced by our company is designed and manufactured with the latest technology and the highest international standard, which is the core part of the European crane. The gear adopts an improved tooth shape design to ensure high bending strength.

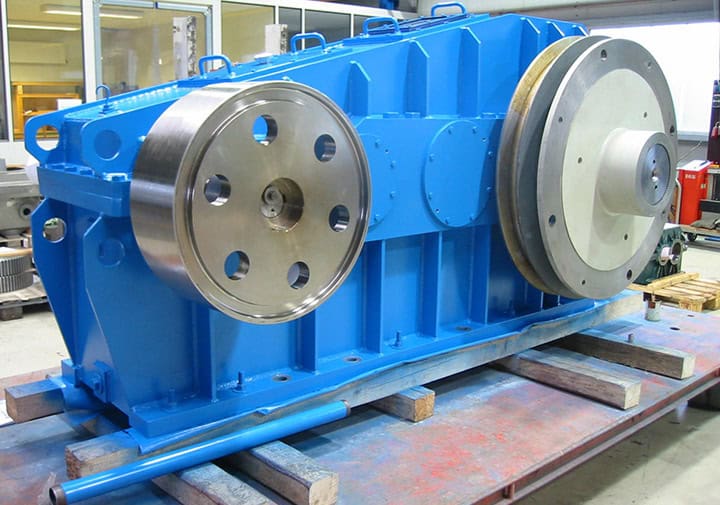

The output shaft of the lifting gearbox we produce is multi-coupled, and the drum has a special connection flange. In addition, the roller can be mounted on the grooves on the gearbox, which is a superior feature to absorb the roller load.

It has a magnificent compact and harmonious gearbox, motor and brake blocks. Also, it has a noiseless working system. Easy to install, disassemble and maintain.

Horizontal gearboxes consist of helical gears, while for vertical gearboxes, the reduction gear is provided through spur gear transmission. The materials required for gears are usually forged from high-grade alloys or carbon steel. Gear teeth are precisely cut with a metric modular system, according to appropriate standard specifications. The housing is made of cast iron and machined to precision tolerances to ensure perfect alignment of the gears. Anti-friction bearings are used for long service life and high efficiency.