Gantry cranes can be classified according to the structure of the door frame, the form of the main beam, the structure of the main beam, and the form of use.

Classification by door frame structure

Gantry crane

1. Full gantry crane: the main beam has no overhang, and the trolley moves within the main span;

2. Semi-gantry crane: The outriggers have height differences, which can be determined according to the civil engineering requirements of the site.

Cantilever gantry crane

1. Double cantilever gantry crane: The most common structural form, the stress of the structure and the effective use of the site area are reasonable.

2. Single cantilever gantry crane: This structural form is often selected due to site constraints.

Classified by main beam form

1.Single main beam

The single main girder gantry crane has a simple structure, is easy to manufacture and install, and has a small mass. The main girder is mostly a deflection box frame structure. Compared with double main girder gantry crane, the overall stiffness is weaker. Therefore, this form can be used when the lifting capacity Q≤50t and the span S≤35m. Single girder gantry crane door legs are available in L-type and C-type. The L-type is easy to manufacture and install, has good stress resistance, and has a small mass. However, the space for lifting goods to pass through the legs is relatively small. The C-shaped legs are made in an inclined or curved shape to create a larger lateral space so that goods can pass through the legs smoothly.

2. Double main beam

Double main girder gantry cranes have strong load-bearing capacity, large spans, good overall stability, and many varieties. However, compared with single main girder gantry cranes with the same lifting capacity, their own mass is larger and the cost is higher. According to the different main beam structures, it can be divided into two forms: box beam and truss. Generally, box-shaped structures are used.

Classified by main beam structure

1.Truss beam

The structural form welded by angle steel or I-beam has the advantages of low cost, light weight and good wind resistance. However, due to the large number of welding points and the defects of the truss itself, the truss beam also has shortcomings such as large deflection, low stiffness, relatively low reliability, and the need for frequent detection of welding points. It is suitable for sites with lower safety requirements and smaller lifting capacity.

2.Box beam

Using steel plates welded into a box structure, it has the characteristics of high safety and high stiffness. Generally used for large-tonnage and ultra-large-tonnage gantry cranes. As shown in the picture on the right, MGhz1200 has a lifting capacity of 1,200 tons. It is the largest gantry crane in China. The main beam adopts a box girder structure. Box beams also have the disadvantages of high cost, heavy weight, and poor wind resistance.

3.Honeycomb beam

Generally refers to “isosceles triangle honeycomb beam”, the end face of the main beam is triangular, there are honeycomb holes on the oblique webs on both sides, and there are chords on the upper and lower parts. Honeycomb beams absorb the characteristics of truss beams and box beams. Compared with truss beams, they have greater stiffness, smaller deflection, and higher reliability. However, due to the use of steel plate welding, the self-weight and cost are slightly higher than that of truss beams. It is suitable for sites or beam sites with frequent use or heavy lifting capacity. Since this beam type is a patented product, there are fewer manufacturers.

Classification by use form

1. Ordinary gantry crane

2.Hydropower station gantry crane

It is mainly used for lifting, opening and closing gates, and can also be used for installation operations. The lifting capacity reaches 80 to 500 tons, the span is small, 8 to 16 meters, and the lifting speed is low, 1 to 5 meters/min. Although this kind of crane is not frequently lifted, the work is very heavy once it is used, so the work level must be appropriately increased.

3. Shipbuilding gantry crane

Used to assemble the hull on the slipway, two lifting trolleys are always available: one has two main hooks, running on the track on the upper flange of the bridge; the other has a main hook and an auxiliary hook, on the lower flange of the bridge. Run on rails to flip and lift large hull segments. The lifting capacity is generally 100 to 1500 tons; the span is up to 185 meters; the lifting speed is 2 to 15 meters/min, and there is a micro movement speed of 0.1 to 0.5 meters/min.

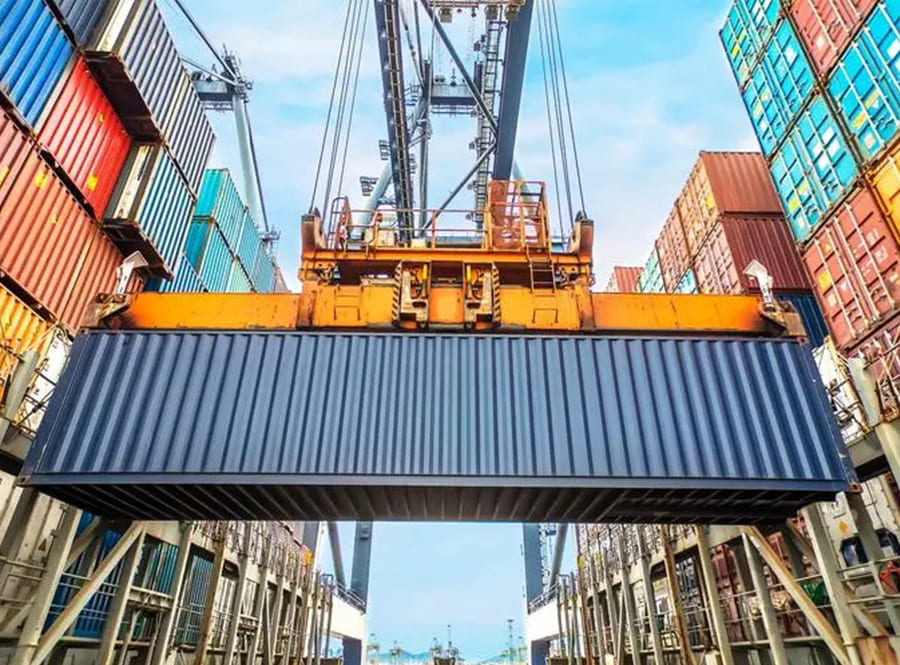

4. Container gantry crane