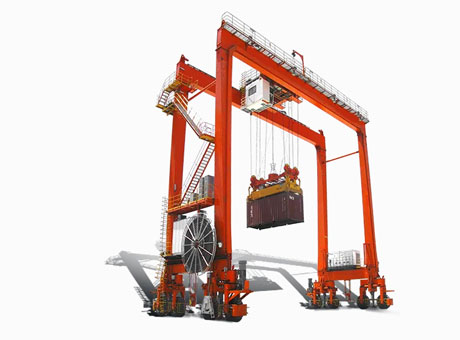

The industrial electric rubber tired gantry crane is a wheeled crane using a special chassis. It has good lateral stability and can perform full-rotation operations. It is often used in relatively fixed operating locations and hoisting operations with large workloads. Next, this article will introduce the relevant characteristics, application fields and repair and maintenance methods of tire-type gantry cranes.

Flexible in action

The rubber tyred gantry crane can walk in a straight line along its normal lane, and can turn the traveling wheels 90˚ to walk at right angles to the original road. It can also turn the traveling wheels to a certain angle for self-rotating walking in the yard, making it easier for the crane to turn around.

High degree of automation

The electrical drive of each main working mechanism of the crane is fully digital AC frequency conversion and PLC control speed regulation. The lifting mechanism also has the function of constant power speed regulation control.

Safe and reliable operation

The gantry crane is equipped with various safety devices to ensure reliable and safe operation and reduce the incidence of accidents.

Easy to operate

Under load conditions, the lifting mechanism and the trolley operating mechanism can work separately or simultaneously, and the trolley traveling mechanism and the trolley running mechanism can also work separately or simultaneously.

Industrial field

It is suitable for cargo loading, unloading, transportation and hoisting in factories, warehouses, workshops and other places. Assists in material transportation, equipment installation and maintenance during the production process, improves production efficiency and reduces worker labor intensity.

Construction sector

It is suitable for hoisting construction materials, equipment and personnel and assists in the construction and construction of buildings. Due to its flexibility and mobility, and the heavy duty electric rubber tired gantry crane can adapt to the needs of different construction sites and environments.

Port ship

Rubber-tyred cranes can adapt to the complex environment of ports and terminals, improve cargo handling efficiency and transportation safety, and improve the efficiency of cargo lifting and handling in ports and on ships.

Mining and civil engineering fields

It can be used to assist the mining, transportation and loading of mines and the construction of construction projects.

Repair methods for common faults of tire-type gantry cranes

Maintenance measures for wire ropes

First of all, when the crane is working, the load is not allowed to exceed the specified rated weight, and a lifting weight limiter device must be installed on the machine. Secondly, it is necessary to select the appropriate steel wire rope according to the working type and environment of the crane. Since the double-wound rope is more flexible than the single-wound rope, it is widely used in practice. During use, the steel wire can be twisted into strands, and then the strands are twisted around the core of the wire to form a rope. In practice, the commonly used rope core is hemp core, but metallurgical cranes often use metal core steel wire or asbestos core to work, and the rope core needs to be impregnated with lubricating oil before making the rope, so as to reduce the risk of Damage occurs due to friction between wire ropes. The third is that when ascending or descending, the movement should be as gentle as possible, and try to avoid the sudden impact force that increases the instantaneous load on the wire rope. In normal times, it is necessary to maintain the wire rope regularly and do Good for its lubrication work.

Repair and maintenance of reduction gears

First of all, in actual work, unless there are specific circumstances, it is forbidden to suddenly reverse the crane, and it is not allowed to use the gantry crane with an overload. The movements of the crane must be smooth and slow when starting and braking. The second step is to check the cleanliness of the crane’s lubricating oil. If it is found that the lubricating oil used is not clean enough, it must be replaced in time. The third is that when using lubricants, you should choose the appropriate model according to the actual situation, and replace the lubricants in time to ensure that the crane casing is clean.

Repair methods for track system failures

In order to avoid the occurrence of rail system failure problems, users of gantry cranes need to make the rails meet various working conditions that may occur during the use of the electric rubber tired gantry crane for sale during the crane installation stage. If it is found that the length of the track from the stop end is less than 15 meters, it must be replaced with a track longer than 15 meters in order to be strong, stable and safe. During routine maintenance of lifting equipment, maintenance personnel need to promptly reinforce loose parts in the track lines. If the bending and deformation of the lifting equipment operating track is serious, relevant personnel need to cut off the problematic line and complete the line replacement in a timely manner. In order to avoid the problem of track height difference, maintenance personnel can use a total station to measure the track height difference. When the height difference between the tracks is difficult to meet the operating requirements of the gantry crane, maintenance personnel can adjust the track spacing by adding section heating sheets.