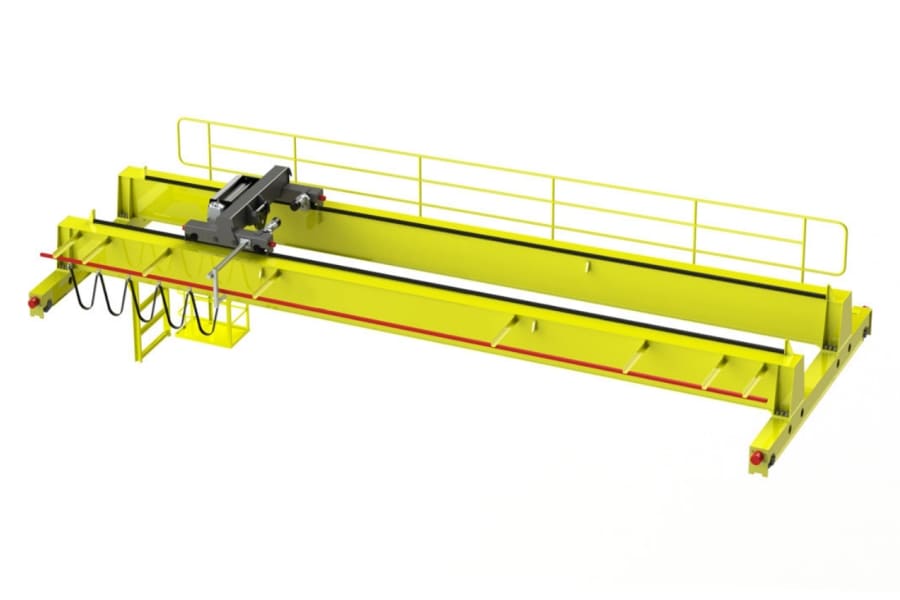

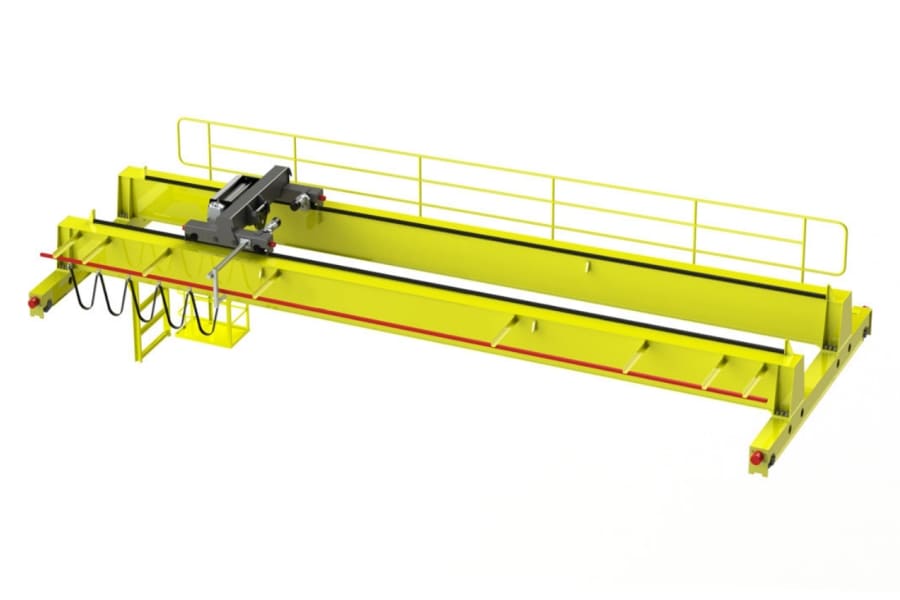

Un under running crane, also known as an underhung crane or underhung bridge crane, is a type of overhead crane that operates on an elevated runway system. Unlike a top running crane where the bridge girder is supported on top of the runway beams, an under running crane’s bridge girder is supported from below by the runway beams.

Here are some key features and components of an under running crane:

Bridge Girder: The bridge girder is the horizontal beam that spans the distance between the end trucks. It supports the hoist and trolley, allowing them to traverse along the length of the crane.

Carros de testa: Los carros de testa se ubican en cada extremo de la viga del puente y alojan las ruedas que se desplazan sobre las vigas de la pista. Proporcionan soporte y estabilidad a la grúa.

Runway Beams: The runway beams are the horizontal beams that support the crane system. In the case of an under running crane, they are typically suspended from the building structure and support the weight of the bridge girder and the loads being lifted.

Hoist and Trolley: The hoist and trolley system is mounted on the bridge girder and is responsible for lifting and moving loads. The hoist mechanism raises and lowers the load, while the trolley mechanism allows horizontal movement along the length of the bridge girder.

Pendant or Remote Control: Under running cranes are usually operated using a pendant control station or a remote control device. This allows the crane operator to control the movement of the hoist, trolley, and bridge girder.

Under running cranes are commonly used in facilities where headroom is limited or when there is a need to maximize the available vertical space. They provide efficient and precise material handling solutions for various industries, including automotive, manufacturing, warehousing, and more. The under running design allows for smooth movement and flexibility in navigating work areas while providing reliable lifting capabilities.