We know that currently commonly used electric hoists can be divided into two types: wire rope polipasto eléctrico con carro and chain electric hoists according to different lifting mechanisms. The electric chain hoist is the most basic and common electric hoist, but do you really understand the polipasto grúa eléctrico?

Origin carro elevador is also called electric chain hoist or electric inverted chain. Its lifting capacity is generally 0.1 to 60 tons, and its lifting height is 4 to 120 meters. It combines the advantages of wire rope electric hoist and manual hoist, and the design is more advanced and reasonable. Therefore, the electric chain hoist has beautiful appearance, small size, light weight, high strength and toughness, safe and reliable use, and easy maintenance. , easy to operate and durable, it is widely used in production lines, assembly lines, assembly machines, logistics transportation and other occasions in modern industries such as machinery manufacturing, electronics, automobiles, shipbuilding, workpiece assembly, and high-tech industrial zones. I beam electric hoist excellent quality can be better demonstrated for operations in warehouses, docks, ingredients, hanging baskets and work sites with narrow spaces.

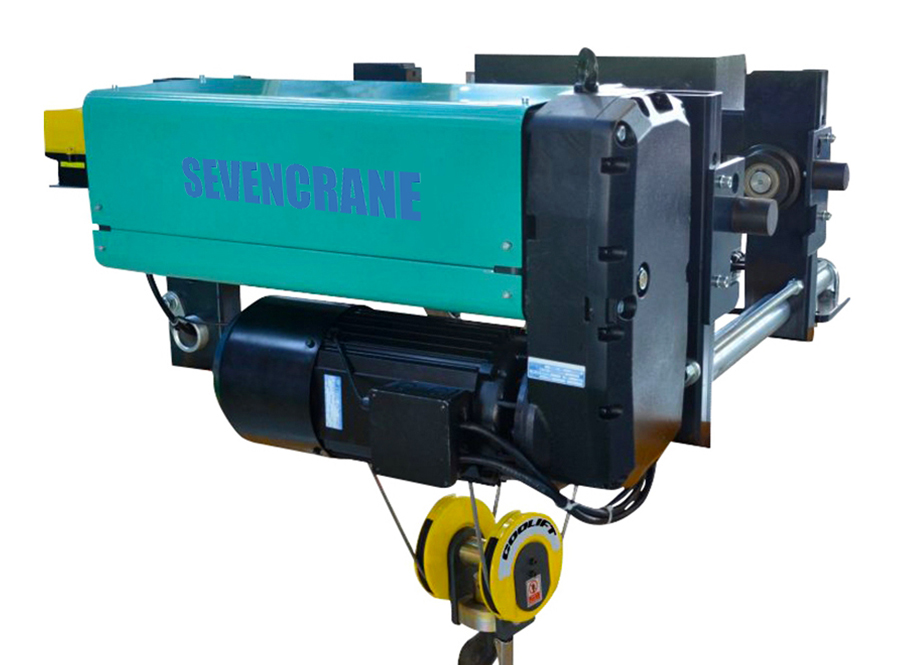

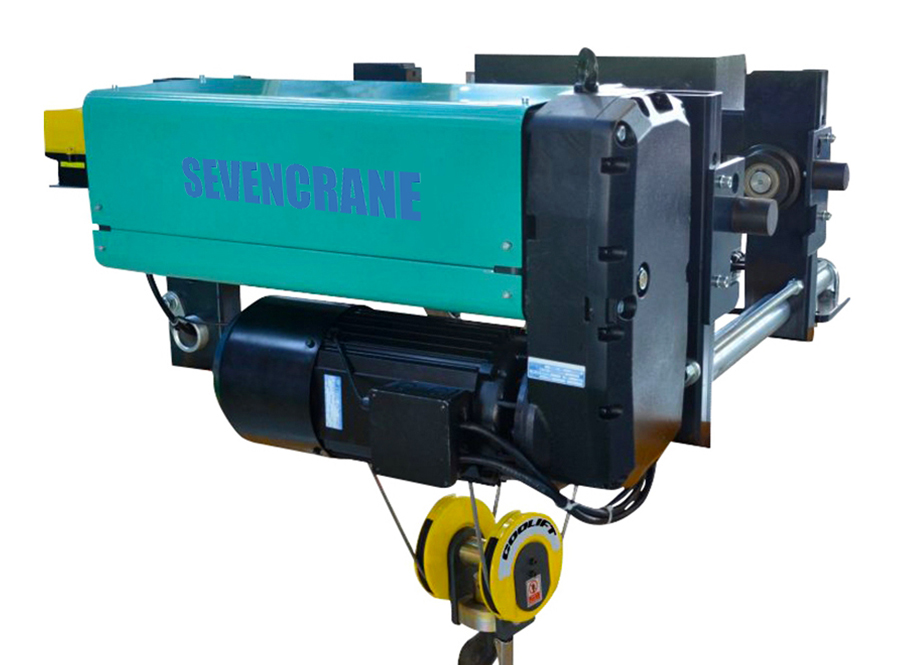

Structural composition A conventional electric chain hoist is mainly composed of three parts: a lifting mechanism, an operating mechanism and a control system. The lifting mechanism refers to the hoist body, which is mainly composed of five devices: driving device – motor, transmission device – reducer, braking device – brake, overload device – overload protection, retrieval device – hook, sprocket, chain, etc. At this stage, electric chain hoists already use a three-in-one device, which is no longer subdivided into drive, transmission and braking devices. The running mechanism refers to the running car, which can also be divided into four devices (fixed and manual structures are relatively less): driving device-motor, transmission device-reducer, braking device-brake, and wheel device-wheel. The control system mainly includes transformers, lifting limit switches, manual button switches, etc.

working principle

1. Source of power. The core component of the electric hoist, the motor, is the main driving force when lifting heavy objects and promotes the operation of the electric hoist.

2. Improve sources. The lifting chain guide wheel drives the chain to lift the heavy object vertically, the motor plays the role of power, and the sprocket and chain play the role of lifting the heavy object. At the same time, it ensures the safety and stability of the chain during operation.

3. Braking source. The braking system plays an effective braking role. The reducer and brake work together to ensure that the hoist is safer and more orderly during operation.

Classification polipasto eléctrico de alta resistencia are mainly divided into three types: fixed type, hand push type and electric type according to the power source. All three have their own advantages and disadvantages, and the actual choice should be made based on different actual needs. Because there are many manufacturers of electric chain hoists at home and abroad, and each brand has its own model naming, performance characteristics, specifications and sizes, it is impossible to choose the equipment suitable for your own company simply based on the brand and model. It is recommended that when selecting, you must decide the final equipment specifications based on your actual use needs, site conditions and working environment conditions.