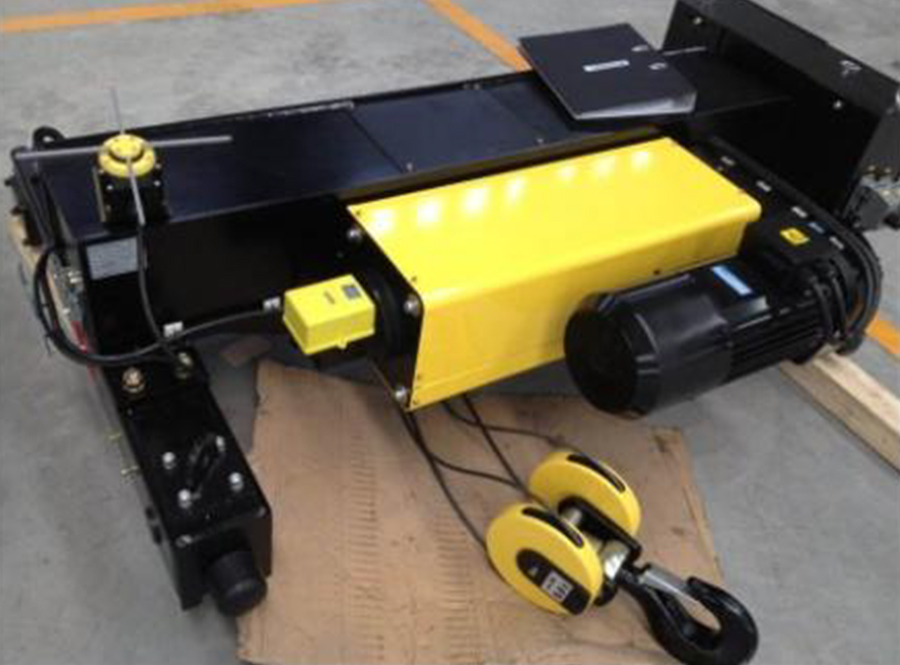

ElThe 1 ton wall mounted jib crane consists of a bracket, jib installation, swivel installation and electric hoist (electric chain hoist). The bracket is fixed on the wall or steel structure column and can be rotated according to user needs. The rotating part is divided into manual rotation and electric rotation. Electric hoists (electric chain hoists) are installed on cantilever rails and are used to lift heavy objects. Cantilever cranes are widely used in light and small lifting applications in mines, workshops, assembly lines, warehouses, and docks. The utility model has the advantages of novel structure, reasonableness, simplicity, convenient operation, sensitive rotation, light weight, and sensitive load movement. The operation of this machine is realized through the handle control button, which controls the lifting and horizontal walking of the sevencrane 1 ton wall mounted jib crane. Polipasto eléctrico de cable de 1 tonelada is a high-end lifting product of Lion Crane. It is increasingly valued by lifting agents in various markets across the country. More and more agents choose to join Sevencrane. Today we will focus on common faults and troubleshooting methods of electric chain hoists.

If an Suministro de fábrica de polipasto de cable eléctrico de 1 tonelada, precio encounters problems during use, we must gradually check the cause of the failure through troubleshooting methods, and remember not to take chances. If the electric chain hoist cannot work normally, the following situations generally occur:

(1) First determine whether the power supply system supplies power to the electric chain hoist. Generally, a test pen is used to test whether there is power input, etc.

(2) When the electrical appliances in the main circuit and control circuit of the electric chain hoist are damaged, the circuit is disconnected or the contact is poor, the motor cannot be energized. In this case, the main circuit and control circuit need to be overhauled, and during the maintenance period, abnormal noise in the power supply of the three-phase motor of the main circuit and control circuit should be prevented to prevent the motor from burning; when the Venta caliente de polipasto de cable eléctrico de 1 tonelada en venta motor suddenly loses power, To avoid damage, the power cord must be disconnected immediately.

(3) When the Fabricante de polipastos eléctricos de cable de 1 tonelada motor voltage is lower than the rated voltage by 10%, the motor starting torque is too small, the electric chain hoist cannot move goods, and cannot work normally, use a multimeter or voltmeter to measure the voltage of the motor input terminal. After inspection, if it is determined that the voltage is too low and cannot work properly, wait until the system voltage returns to normal before continuing the operation; sometimes, the voltage of the electric chain hoist motor is normal, but it cannot work normally, which requires other reasons to be considered, such as: The motor is burned out, the Proveedor de polipastos de cable eléctricos de 1 tonelada has not been used for a long time, and the maintenance is not good, causing the brake wheel and end cover to rust (the brake wheel should be removed, the rusted surface should be cleaned, and then the vehicle should be retested), if The motor bursts severely and the motor will not rotate. If you find this situation, you should stop and overhaul or replace the motor to ensure the normal operation of the electric chain hoist. In addition, overloading during hoisting is strictly prohibited. To avoid causing accidents.