Grúas semipórtico are used in conjunction with CD, MD and other types of electric hoists or hoist trolleys. It is suitable for lifting, transportation, loading and unloading operations in stations, wharves, warehouses, construction sites, machinery or structure assembly yards, power stations and other open-air workplaces. It is also suitable for indoor workshop.

In contrast to a gantry crane, semi gantry crane uses the structure of the plant rather than new legs on the crane itself. Undoubtedly, price of semi gantry crane is much better. Considering that the grúa semipórtico is not entirely dependent on the factory, semi gantry crane cost is reasonable and low.

Gantry cranes are complex machines consisting of numerous parts. The following are some of the main parts of a grúa semipórtico:

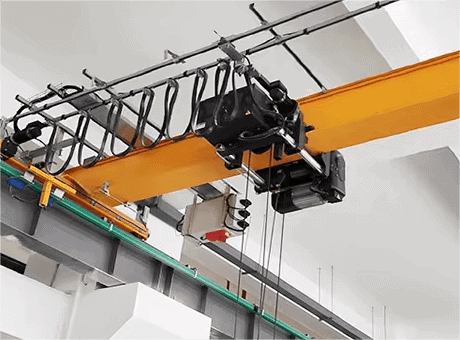

Girder: The horizontal beam along which the trolley travels. In a semi gantry crane, this is usually a single solid beam, but in larger, more complex systems, it may be a double beam.

Hoist: The device actually lifts the load. It is usually a wire rope or electric chain hoist that runs a trolley along the beam.

Trolley: The trolley moves back and forth along the main beam, carrying the hoist. The movement of the trolley allows the load to move horizontally.

Supporting structure (outriggers): The outriggers are vertical or near-vertical beams that support the girder, which can be fixed or movable, depending on the design of the crane.

Controls: The operating system that controls the movement of the crane. This can be a wired pendant, remote control or cabin control.

Drives: These motors move the trolley along the girder and move the entire crane along the runway.

Power system: Single girder semi gantry crane uses a motor to provide power. For some smaller cranes, this can be electric or even manual.

Cables and wires: They transmit power and control signals to the different parts of the crane.

Braking system: Safely stops the movement of the crane when needed.