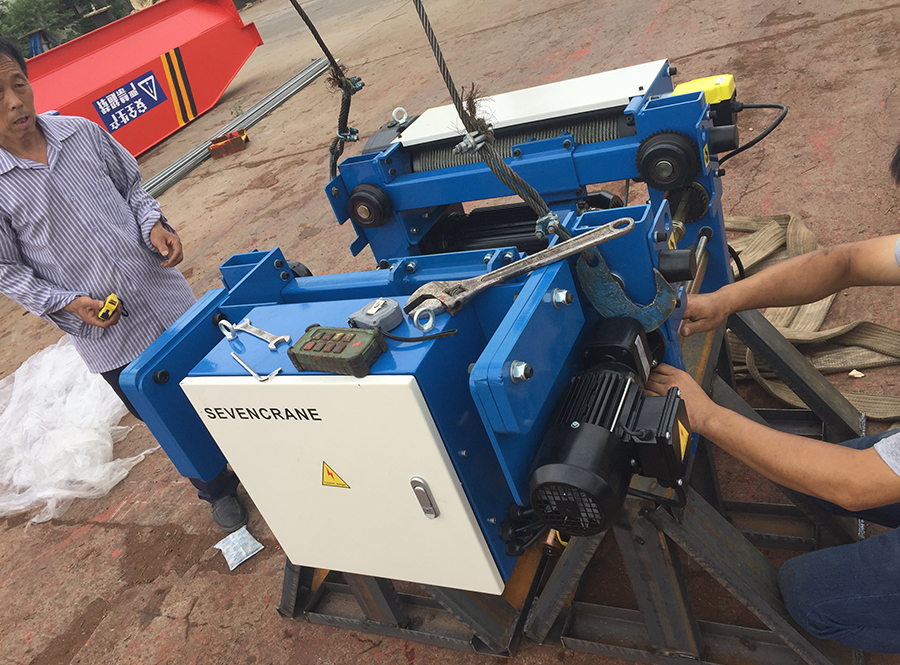

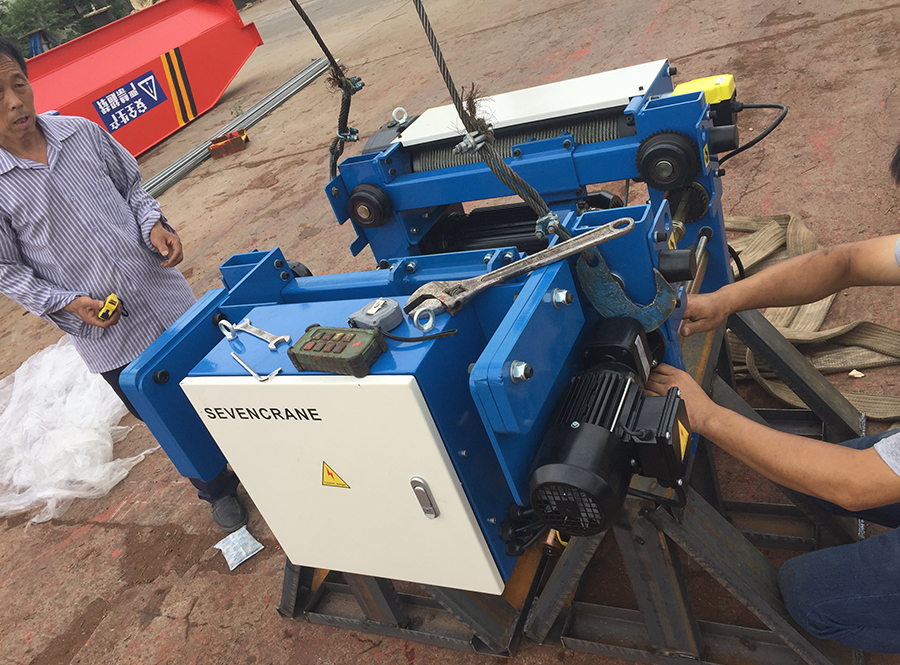

ElThe 1 ton wall mounted jib crane consists of a bracket, jib installation, swivel installation and electric hoist (electric chain hoist). The bracket is fixed on the wall or steel structure column and can be rotated according to user needs. The rotating part is divided into manual rotation and electric rotation. Electric hoists (electric chain hoists) are installed on cantilever rails and are used to lift heavy objects. Cantilever cranes are widely used in light and small lifting applications in mines, workshops, assembly lines, warehouses, and docks. The utility model has the advantages of novel structure, reasonableness, simplicity, convenient operation, sensitive rotation, light weight, and sensitive load movement. The operation of this machine is realized through the handle control button, which controls the lifting and horizontal walking of the sevencrane 1 ton wall mounted jib crane. motorized chain hoist is an important part of the chain hoist and also the core load-bearing component. The editor of Lanchuang Lifting found that among the electric chain hoists that were repaired, technicians identified that a large part of them were caused by the user not lubricating the hoist chain for a long time. Lubricating the load-bearing chain is a very important part of chain hoist chain maintenance. Applying the load-bearing chain regularly can not only reduce the noise caused by friction, but also extend the service life of the hot sale motorized chain hoist for sale.

The role of lubricating oil

1. Lubrication: Factory supply motorized chain hoist price lubrication can reduce hoist friction, increase the coefficient, and turn dry friction into wet friction;

2. Efecto de enfriamiento para evitar que la cadena se oxide;

3. The lubricating grease itself has no corrosive effect on the chain, and motorized chain hoist manufacturer also plays a role in isolating the corrosion of moisture and other impurities in the air. At the same time, it can also neutralize the corrosion of the chain caused by excessive acid and alkali;

4. Damping effect: Friction and vibration are inevitable during the lifting process. However, due to the existence of the lubricating oil film, the mechanical energy generated by the vibration is absorbed by the oil film and converted into internal friction heat, thereby reducing the force of machine vibration through the friction of the liquid. , so that the equipment runs smoothly;

5. Cleaning effect: The friction particles generated during the friction process of the chain, as well as impurities in the surrounding environment, can accelerate the wear and tear of the chain surface, and the lubricating oil can wash them out of the body;

6. Efecto de sellado: el aceite lubricante no solo lubrica y reduce la fricción, sino que también mejora el sellado. La grasa lubricante también tiene una función especial en la formación de un sello, que puede evitar la entrada de vapor de agua u otro polvo e impurezas;

Oil the load chain:

1. Clean and wipe the impurities and dust attached to the surface of the chain. If it has been used for a long time and has a lot of dirt attached to it, soak the chain in kerosene and then clean it with a soft-bristled brush; wipe it with a clean rag after cleaning. Dry;

2. Lubrication: When the load chain is in an unloaded state, move it back and forth to fully lubricate it;

3. Full lubrication: After adding lubricating oil, start the hoist and make the chain run up and down to allow the lubricating oil to fully lubricate the chain and sprocket.