Overhead electric overhead cranes, also known as electric bridge cranes, are advanced material handling solutions that offer exceptional lifting capabilities and precise control. These cranes utilize electric power for efficient and seamless movement, making them an indispensable asset in various industrial sectors. In this article, we will explore the features, advantages, and applications of overhead electric overhead cranes, highlighting their role in powering efficiency and precision in material handling operations.

- Definition and Components:

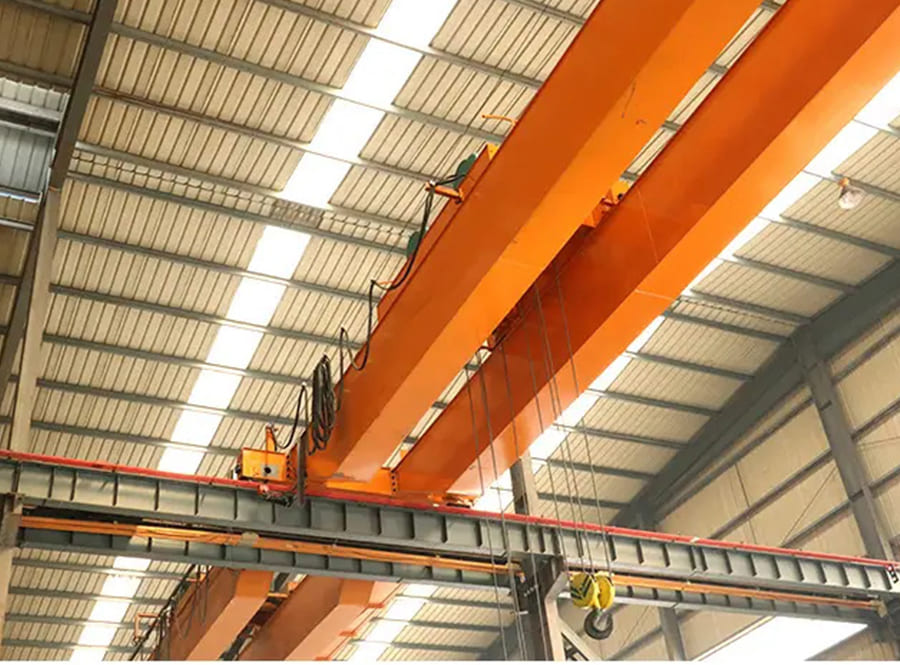

An overhead electric overhead crane is a type of crane system that utilizes electric power to provide vertical lifting and horizontal movement capabilities. The crane consists of several essential components, including a bridge or runway, end trucks, electric hoist, trolley, power supply, and controls. The electric power source drives the motors that control the movement of the crane, enabling efficient and precise material handling. - Efficient and Precise Movement:

The electric power system in overhead electric overhead cranes offers several advantages in terms of movement efficiency and precision. Electric motors provide smooth acceleration and deceleration, allowing for controlled and precise positioning of loads. The ability to fine-tune movement speed and direction enhances the overall productivity and safety of material handling operations. - Increased Lifting Capacity:

Overhead electric overhead cranes are designed to handle heavy loads with ease. They have high lifting capacities, ranging from a few tons to several hundred tons, depending on the specific configuration and requirements. The electric power system ensures consistent and reliable lifting performance, enabling the safe and efficient movement of heavy materials or equipment. - Versatilidad y personalización:

Overhead electric overhead cranes can be customized to suit various operational requirements. They can be tailored in terms of span, lifting capacity, lifting height, and additional features such as specialized lifting attachments or automation capabilities. This versatility allows businesses to optimize the crane system to match their specific material handling needs, enhancing efficiency and adaptability. - Funciones de seguridad mejoradas:

Safety is a top priority in material handling operations, and overhead electric overhead cranes are equipped with advanced safety features. These features may include overload protection, emergency stop buttons, limit switches to prevent over-travel, anti-collision devices, and safety devices to prevent the crane from operating outside its designated area. Adhering to proper safety protocols and providing operator training ensures safe and secure material handling operations. - Aplicaciones:

Overhead electric overhead cranes find applications across various industries and tasks. They are commonly used in manufacturing plants for lifting and moving heavy machinery, components, and raw materials. In warehouses, they facilitate efficient loading and unloading of goods. Industries such as automotive, steel, construction, and logistics rely on overhead electric overhead cranes for their high lifting capacities and precise control. - Energy Efficiency:

Electric power systems in overhead electric overhead cranes offer energy efficiency compared to traditional diesel-powered cranes. Electric cranes eliminate the need for fuel consumption and reduce emissions, making them environmentally friendly and cost-effective in the long run. Moreover, advancements in electric motor technology have improved energy efficiency, reducing overall power consumption during crane operation. - Mantenimiento y Durabilidad:

Regular maintenance and inspections are crucial for optimal performance and longevity of overhead electric overhead cranes. Routine checks of electrical components, lubrication of moving parts, and addressing any signs of wear or damage contribute to the reliability and durability of the crane. Proper maintenance ensures that the crane operates efficiently and minimizes the risk of breakdowns or disruptions in material handling operations.

Conclusión:

Overhead electric overhead cranes offer efficient and precise material handling solutions in industrial environments. With their electric power systems, these cranes provide enhanced movement control, increased lifting capacities, and improved safety features. The versatility and customization options of overhead electric overhead cranes make them suitable for a wide range of applications across industries. By integrating these advanced cranes into their operations and prioritizing maintenance, businesses can power efficiency and precision in their material handling processes, leading to improved productivity and operational success.