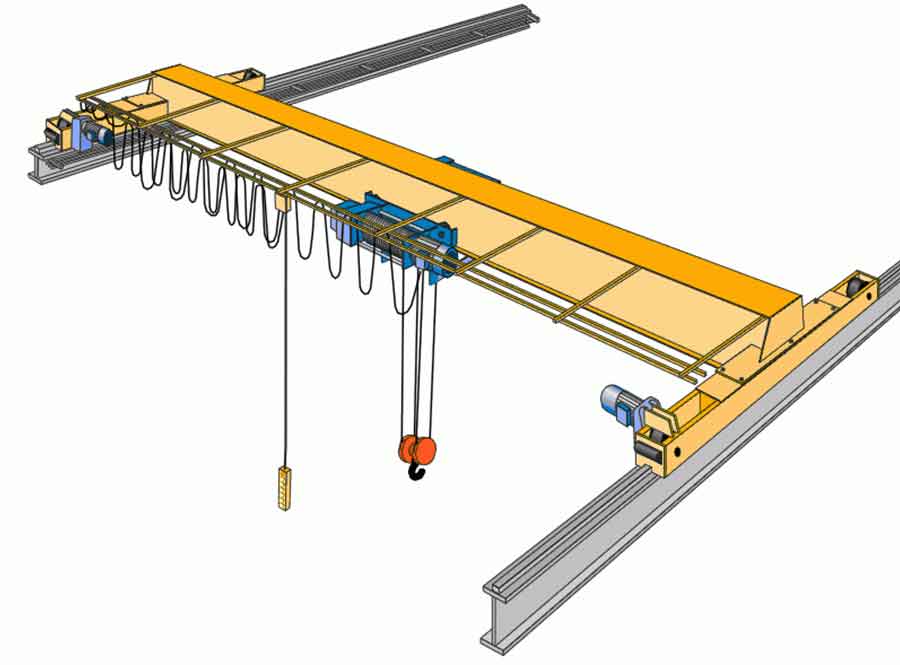

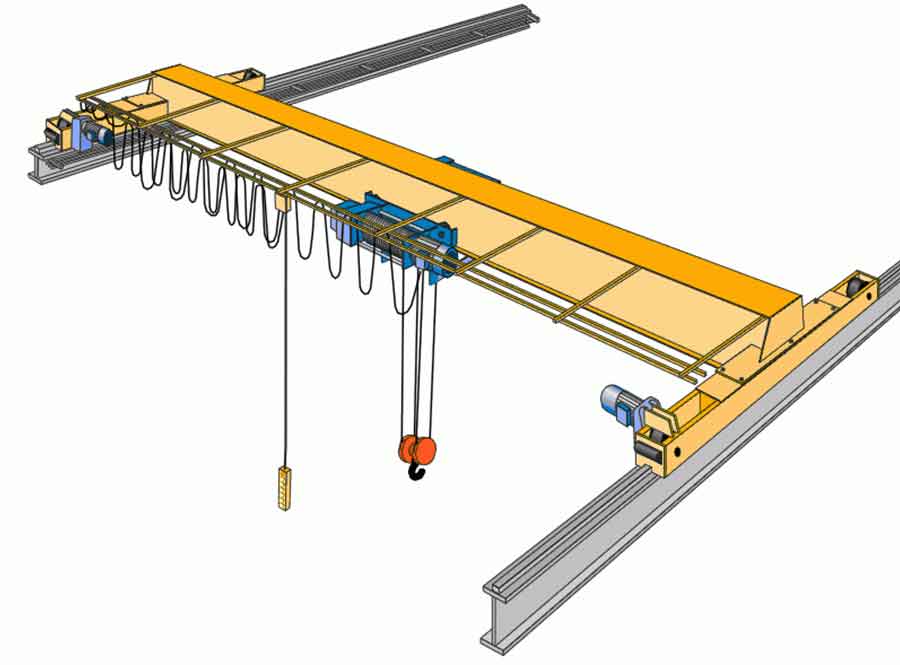

1. The operating mechanism of the overhead traveling bridge crane cart must be equipped with brakes so that the cart can stop safely within the permitted braking range after power failure.

When the sliding distance of the trolley after power failure exceeds the specified value during normal operation, the brakes should be adjusted immediately to ensure that the braking formation meets the requirements.

2. The brakes of the oben laufender Brückenkran should be inspected and adjusted every 2-3 days. The brakes at both ends of the separately driven operating mechanisms should be coordinated to prevent the cart from twisting and gnawing during braking; The brake is fully released without additional frictional resistance, ensuring normal operation of the crane.

3. The trolley should be installed with end-forming limiters, and accordingly stopper safety rulers should be installed at both ends of the sevencrane top running bridge crane for sale trolley stroke to ensure that the trolley touches the stopper arm when it reaches the end of the track. And open the normally closed contacts to shut down the power; a corresponding limit safety contact ruler should be installed between two cranes on the same track. When two cranes collide, they touch each other’s limiter arm and open the contacts to shut down the power to prevent Two large cars collide.

4. The four corners of the industrial top running bridge crane manufacturers bridge must be equipped with spring-type or hydraulic buffers, and a metal frame-type stopper equipped with hardwood or rubber pads is installed at the end of each track of the crane to prevent the crane from derailing. It can also absorb the kinetic energy of the crane’s movement, act as a buffer and shock absorber and protect the crane’s building from damage.

5. Cart wheels with tapered treads are usually used in separate driving situations and should be equipped with rails with a curved top surface. The tapered big end should be installed in the direction of the mid-span and must not be installed backwards.

6. A track sweeper plate should be installed in front of the wheels of the heavy duty top running bridge crane price. The gap between the lower edge of the track sweeper plate and the top surface of the rail is 10mm. It is used to remove debris on the track to ensure safe operation of the crane.