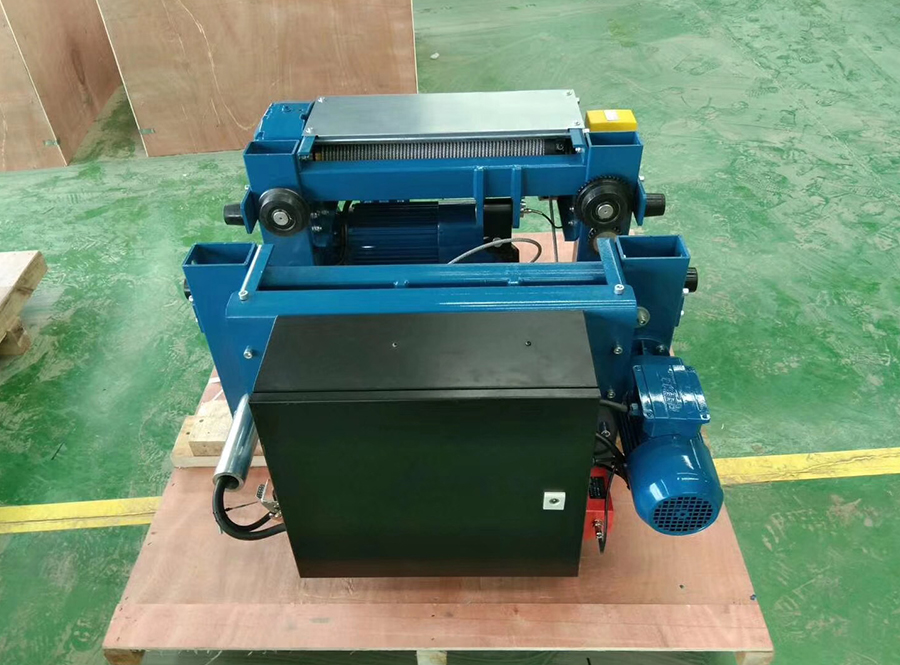

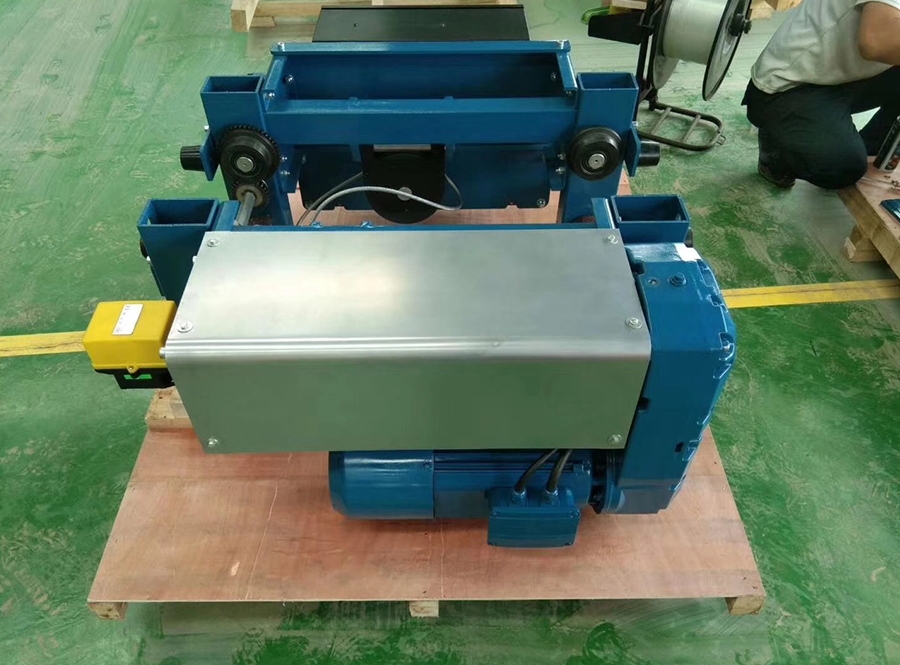

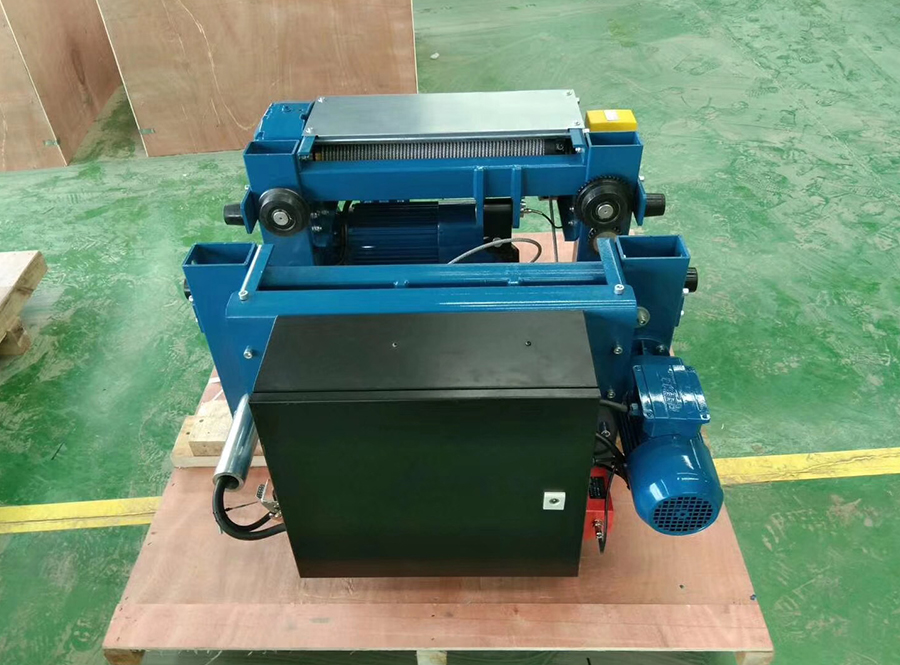

The intelligent multi-stage controllable electric chain hoist with trolley has fast positioning, slow start and stop, and operates at a variety of lifting speeds. It can be adapted to the needs of different users and is widely used in various reciprocating material transportation places and matched with hot sale electric chain hoist with trolley for sale.

Main innovation points:

Use a rotary encoder to measure position pulses, use a controller to calculate the speed based on the number of pulses counted, and use the controller to determine whether the position is in place based on the number of pulses counted to cut off the output;

Use a weighing device to judge the weight and realize fast speed for light load and slow speed for heavy load;

Use frequency conversion technology for speed control to achieve multi-speed, soft start and smooth stop, reducing the impact on the load and factory supply electric chain hoist with trolley price;

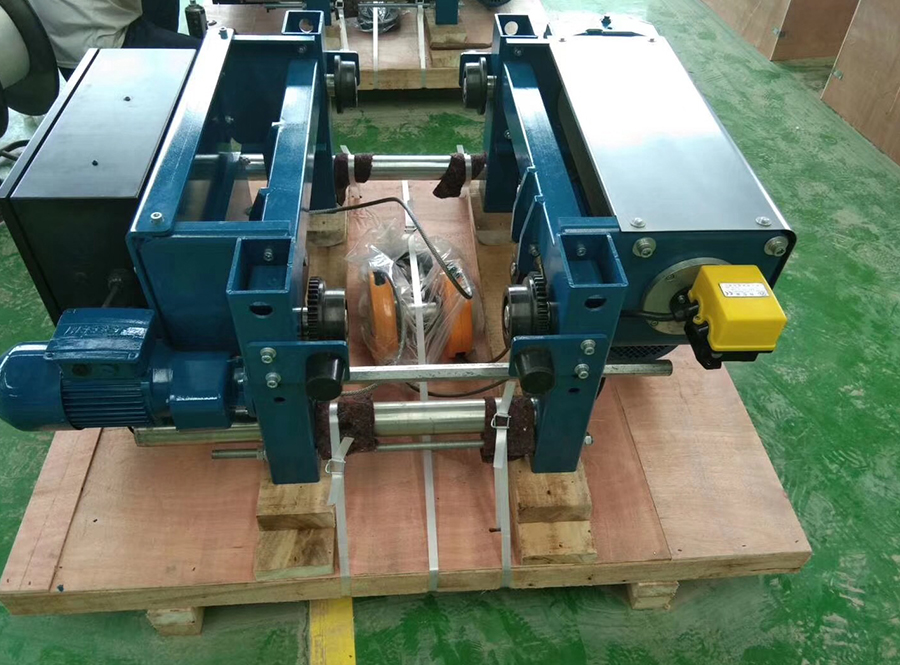

4. The new friction transmission mechanism was patented for invention.

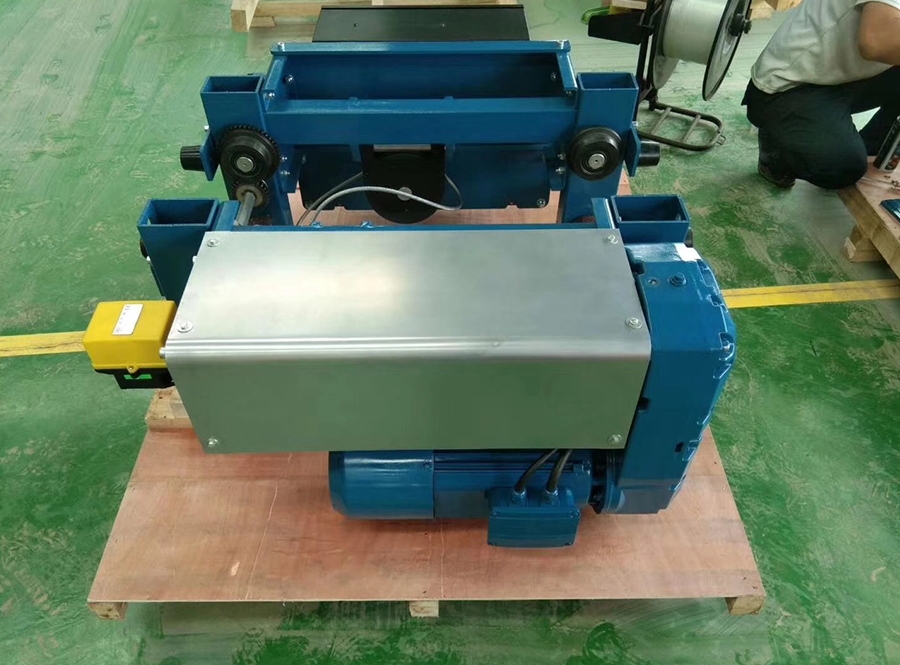

Main performance parameters:

Rated lifting weight: 2.5t; rated lifting speed: 0~6m/min; working level: M5; protection level: IP55; motor speed: 2760/600rpm; working power supply: 380V/50Hz.

Application effect:

1. The gear box is maintenance-free throughout its life cycle: all parts are designed according to the maintenance-free concept, eliminating the need for maintenance during use by customers, being environmentally friendly and clean, and reducing pollution;

2. Development of multi-functional electric chain hoist with trolley manufacturer: achieve a high degree of integration of electrical control functions, and independently develop multi-functional controls such as automatic fault diagnosis, over-current control, wireless input control, phase sequence protection, and working condition recording;

3. Non-metallic materials are used in the chain guide mechanism: a special wear-resistant engineering plastic chain guide cover is used to reduce the chain running noise, reduce chain wear, and effectively increase the chain service life; at the same time, a steel protective sleeve is added outside the chain guide cover , taking into account product safety;

4. Development of a first-level load-limiting shunt braking mechanism: load limiting or motor failure does not affect the braking of the load, improving safety in use;

5. Safety clutch friction plate production: The running speed of the dry friction plate reaches 2800r/min, and the allowed slip time is three times longer than the European standard. Electric chain hoist with trolley supplier can still lift heavy objects normally after slipping, reaching the international advanced level; the service life of the friction plate exceeds the European standard;

6. New friction transmission mechanism reduces axial pressure, small volume design, and stable operation.