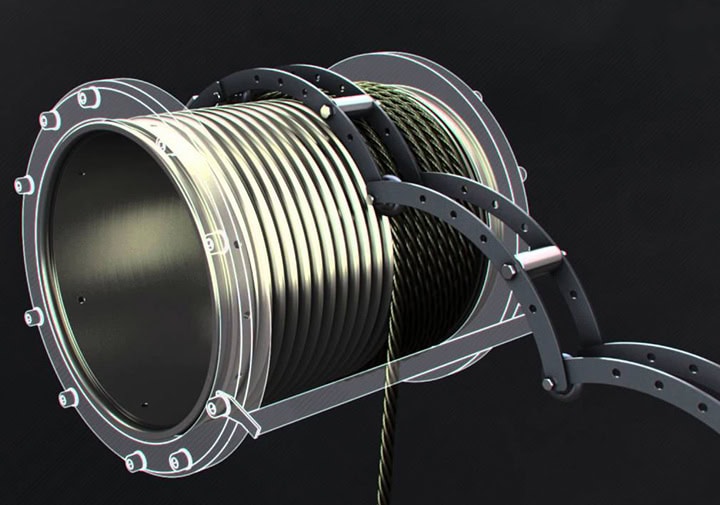

The crane wire rope guide can ensure the normal operation of the electric hoist and prolong the service life of the wire rope and drum. The rope guide is also called the wire rope hoist, which is one of the accessories of the electric hoist. Its function is to make the wire ropes neatly arranged on the reel and prevent the wire ropes from being disordered and overlapping caused by the electric hoist.

Cast from GGG70 material, the crane rope guide ensures the correct winding and unwinding of the rope on the pitch on the drum, with practical assembly and disassembly functions. In some special applications, it can also be used for caster production.

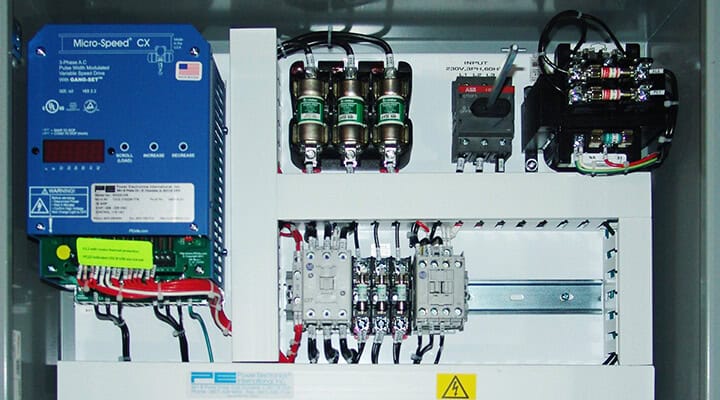

The wire rope guide is a convenient, high-quality, low-cost alternative to almost any brand of wire rope guide, and is generally suitable for small and medium-sized wire rope hoists. Because our wire rope guides are of universal design, they offer quick installation and high-value performance.

Its function is to make the steel wire ropes neatly arranged around the drum, so as to prevent the electric hoist from malfunctioning or even damage to the hoist due to the confusion or overlapping of the wire ropes. If the guide is subjected to a large lateral force during operation, it will cause braking. The rope guide, also known as the rope arrangement device, is to arrange the wire ropes neatly around the drum to prevent the electric hoist from malfunctioning or even damage to the hoist due to chaotic or overlapping wire ropes.