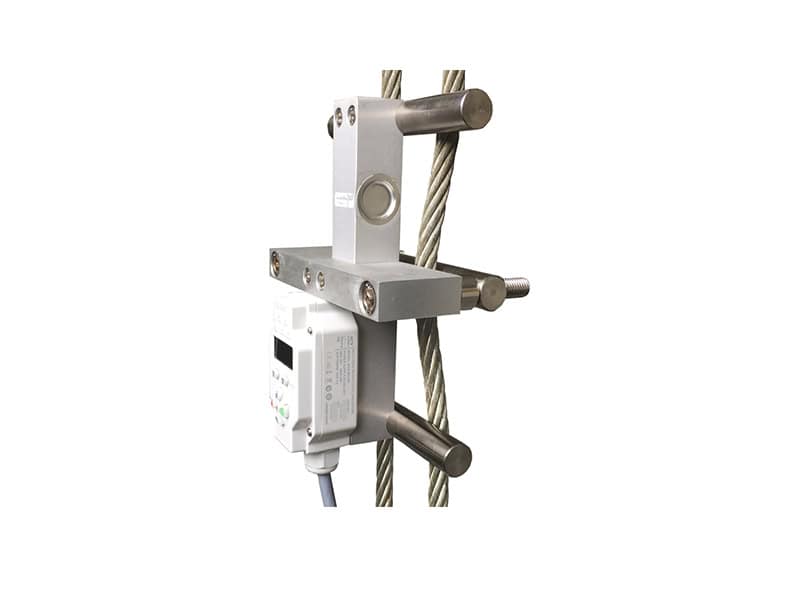

The crane overload protection device usually refers to the overload limiter, which is a safety device installed on the lifting drum, which is used to sense the lifting weight of the bridge crane or gantry crane and prevent overloading. The overload limiter is composed of two parts, the bearing seat sensor and the control instrument, and has functions such as weight digital display, overload automatic alarm, and power failure.

Regardless of type, all overload protection devices work by sensing the force of the load. When the load exceeds the preset percentage of rated capacity (usually 100~125%), the overload protection device will temporarily inhibit the hoist, so that the crane can only lower the load.

Besides, overload protection devices are only useful if they can accurately detect and prevent overloads. Regular maintenance checks are essential to ensure the efficacy of these devices.

Crane overload protection devices are very common in the machinery industry market. However, many crane manufacturers cannot guarantee whether their machines are equipped with overload protection devices. Therefore, when customers purchase a crane, it is essential to verify the presence and effectiveness of the overload protection device in the crane.

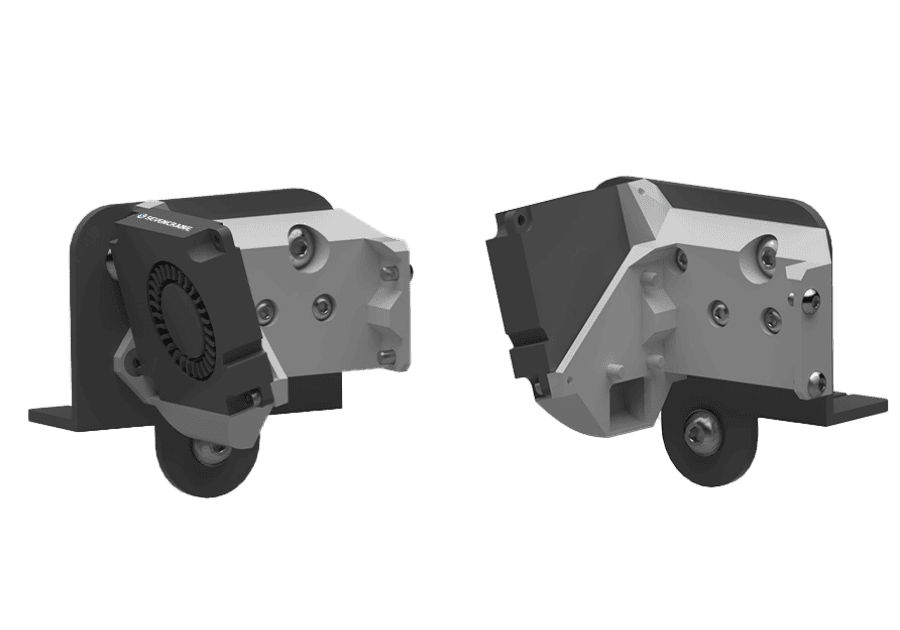

By the way, the crane overload protection device provided by SEVENCRANE to customers is an indispensable safety device for cranes in compliance with work safety and workers’ health, and is also one of the important devices for preventing accidents at your workplace. Moreover, the crane overload protection device produced by our company is easy to disassemble and assemble, easy to debug, and has strong flexibility.