Single girder overhead cranes are designed according to international standards. It is a lightweight material handling equipment with a single beam running on a suspended track, usually equipped with a CD or MD electric hoist. Single girder bridge cranes span 3-15 meters, operating speed 20 m/min and 30 m/min.It can be customized according to service conditions and user requirements.

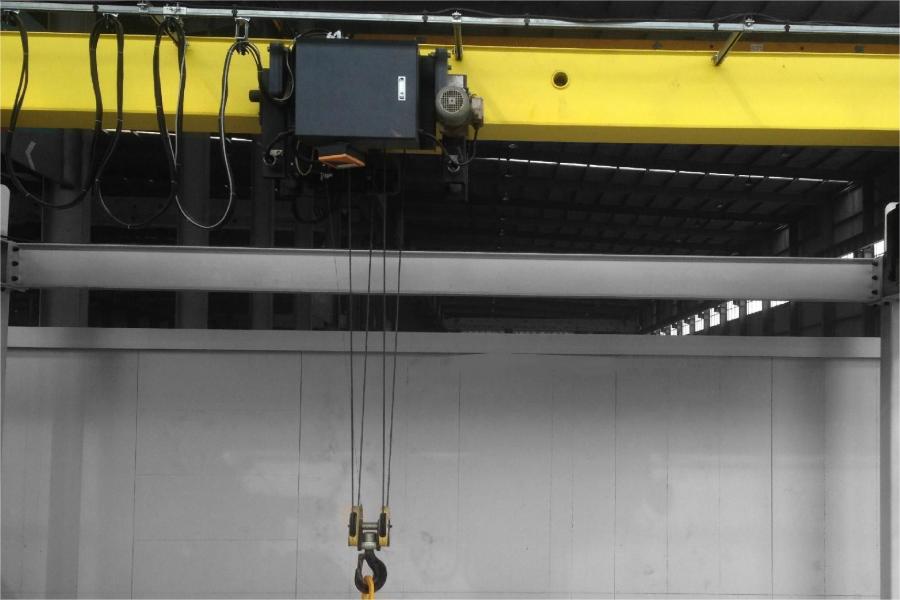

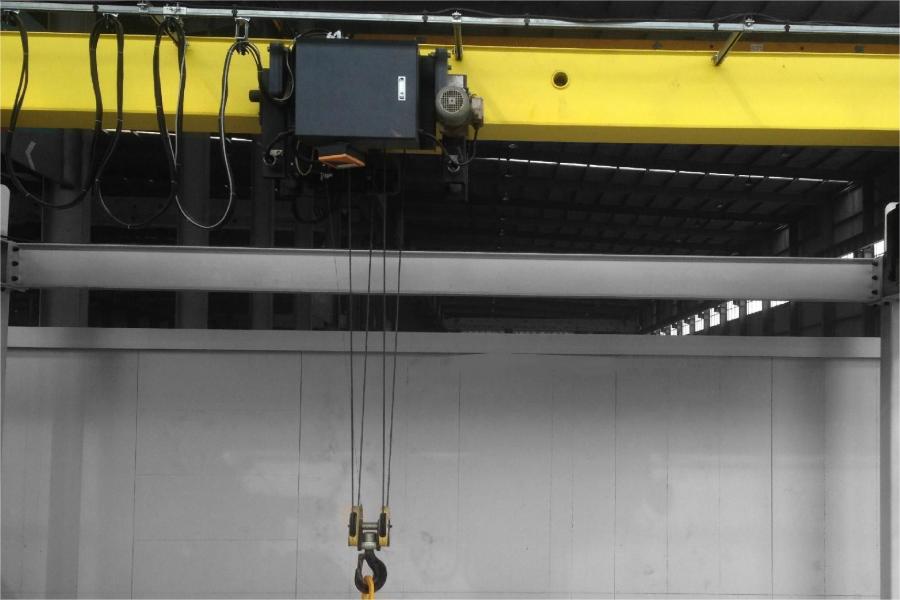

Single girder bridge crane is composed of main beam, cross beam, electric hoist, electrical components, lifting equipment, etc.

Compact girder: Use bias-rail-box-type structure, with optimized design and light self-weight. Steel quality is Q235B or Q345B(international Fe37 or Fe52). Thickened steel plate, the thickness of the steel plate is 7~10mm.

Electric hoist: The hoist employs motor of hoisting mechanism and reducer imported from Germany. Modular design, low clearance, small overall dimension.

Travel device: Each end beam is equipped with double flange wheels, buffer and anti-derailing protection device. The finished end beam is get once positioning on CNC in order to ensure dimension accuracy and fit tolerance.

Single girder overhead crane is usually used in working environments without flammable, explosive or corrosive substances or media, such as mechanical assembly, warehouses, caves, etc.

Overhead crane is widely used and not only offers extremely high safety, good design, ergonomics, easy and efficient material handling, but also saves warehouse space due to its compact size. Used in machinery manufacturing, assembly, warehouses and other places, used in machinery equipment manufacturing, maintenance, warehouses and other places.

Advantages:

- High security and reliability

- Compact structure and good rigidity

- Flexible operation and low maintenance

- Low noise, no pollution

- Wide range of choices and applications

- Smooth movement, effective braking, and long service life.

- High quality and cost-effective crane price