Semi gantry cranes are a type of lifting equipment between bridge cranes and gantry cranes, usually supported by a single or multiple beams, utilizing a ground mounted track and a raised track. This design allows full utilization of available space in the working environment and is widely used in material handling in machine shops.

Main components: lifting mechanism and trolley: main beam; outriggers; end beams; electric control box; operating system; safety protection system, etc.

Advantages:

1. Space saving: Compared with bridge cranes, it reduces the plant space occupied by columns; compared with gantry cranes, it saves production space.

2. Cost-effective: By using the plant structure to replace the new legs of the crane itself, higher cost-effectiveness is achieved.

3. Flexibility: Since it is not completely dependent on the plant, semi-gantry cranes are superior to traditional EOT cranes in flexibility.

4. Safety: It can be installed under the existing bridge crane and equipped with necessary safety devices.

5. Wide range of applications: semi gantry cranes are suitable for indoor and open-air use, providing a variety of solutions, including double-beam and single-beam semi-gantry cranes.

Applications:

Semi-gantry cranes are widely used in the following areas: steel industry; forest product handling; intermodal; biomass/pellet handling; concrete production; warehouses, construction sites, docks, power stations, etc.

(In certain situations, semi-gantry cranes can be equipped with truss-type outriggers to enhance their structural stability.)

There are two typical applications:

- Indoors, usually used under existing overhead cranes to provide more hooks, thereby improving the productivity of the factory.

- Outdoors, often used near buildings, making full use of existing runway structures, thereby improving the cost efficiency of factories or plants.

Based on the carrying capacity, this special type of gantry crane can be divided into single-beam semi-gantry cranes and double-beam semi-gantry cranes.

Semi-gantry crane types

1.Single girder semi gantry crane

Widely used in factory, warehouse, stockyard, etc.

Lifting Capacity: 1~20t

Span: 7.5~20m

Lifting Height: 6/9/12m (according your needs)

Voltage: 220-660V 50/60Hz 3Phase

Working Class: A3, A4

Ambient Temperature: -25~40℃

2.Double girder semi gantry crane

Widely used in factory, warehouse, stockyard, etc.

Lifting Capacity: 1~20t

Span: 7.5~20m

Lifting Height: 6/9/12m (according your needs)

Voltage: 220-660V 50/60Hz 3Phase

Working Class: A5, A6

Ambient Temperature: -25~40℃

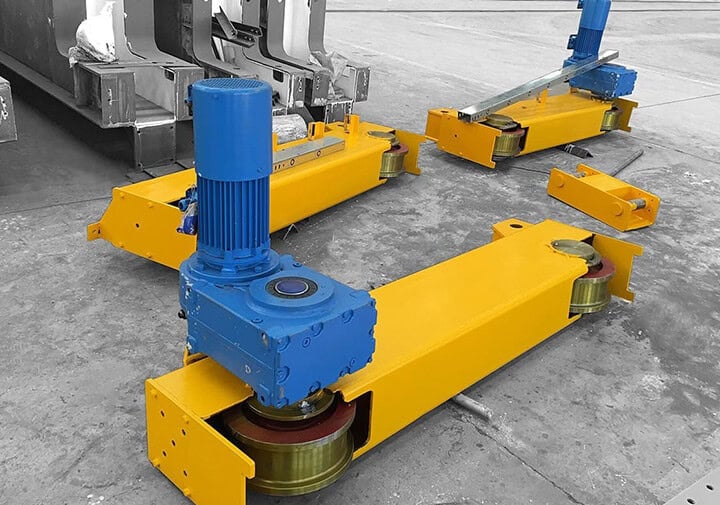

3.Rail-less Semi Portal Crane

Widely used in factory, warehouse, etc.

Lifting Capacity: 1~20t

Span: 7.5~20m

Lifting Height: 6/9/12m (according your needs)

Voltage: 220-660V 50/60Hz 3Phase

Working Class: A3, A4

Ambient Temperature: -25~40℃

Customized Semi-Gantry Crane Design

Our design team uses advanced computer technology to provide customized solutions for each semi-gantry crane system to precisely meet your needs. Whether you are an end user with specific workplace requirements or a trade customer supplying equipment to a third party, we can design semi-gantry cranes of various sizes and capacities for a variety of industries. With our extensive experience, we ensure that each crane is efficient and effective in the task at hand.